The space industry has been revolutionized by the ever-increasing production and launch of smallsats. Additive manufacturing technologies has helped this radical change to be fulfilled as well as have itself reach new heights with the manufacture of structural components for the new generation of space parts using high performance composite materials.

Although much still must be done to reach an extensive use of additive manufacturing for space applications, CRP Technology’s built a considerable experience supplying cutting-edge solutions for space key industry leaders. A clear and remarkable example comes from the experience with LISA.

The Italian-based company specialist for more than 25 years in the use and development of advanced additive manufacturing technologies and materials collaborated with the Laboratoire InterUniversitaire des Système Atmosphérique (LISA) of Universite Paris-est Creteil (UPEC) on the construction of a smallsat that is a 3U cubesat form factor.

The project was carried by students under CNES and Space Campus University supervision.

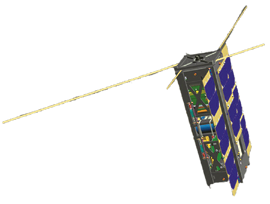

Image above: 3U cubesat OGMS-SA (OutGassing

Material Study by Spectroscopy Analysis) with solar

panels and antennas deployed —

mage is courtesy of LISA

The goal was to develop a demonstrator that can be flight-ready in LEO. The engineering team at LISA and CNES decided to rely on CRP Technology and its Windform® TOP-LINE family of high performance materials for the manufacturing of the smallsat.

The project manager at LISA said that using such a process and composite material from Windform’s® TOP-LINE, the company knew for certain the structure could be designed exactly the way the firm needed it to be designed. The design has been done taking into account all of the constraints. CRP Technology’s support was crucial to achieve all aims.

Their Windform® TOP-LINE materials and additive manufacturing process allowed us to reduce mass and optimize the way to integrate parts inside the cubesat. The structure had to survive vibration tests (to endure the launch) and thermal-vacuum tests. It had also to withstand outgassing requirements.

Cubesat structure is critical, as it has to fulfill the launch-pad (P-Pod) requirements in terms of dimension, flatness and roughness, but also for outgassing, UV resistance, thermal expansion, and general space constraints. Plus, if it breaks, or stays stuck in the P-pod launcher, the mission is over.

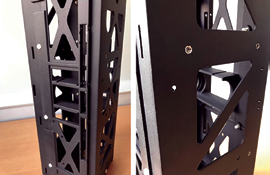

Left: Mechanical solar panel deployment frame

integrated in the 3D printed structure.

Right: Battery Cradle integrated in the 3D printed

structure — photo is courtesy of LISA

The assignment was challenging; however, thanks to the long-term experience gained in the field of additive manufacturing service alongside the key leaders of the most advanced industrial sectors CRP Technology accepted the project. The activity of CRP Technology’s 3D Printing department has been focused from the beginning on maximizing and achieving the targets required, providing full collaboration to the team at LISA.

Work began with an accurate analysis of the 3D and 2D files: through their long-standing technological expertise, CRP Technology suggested alterations that made it possible to optimize the geometries of the parts, reaching the required target in terms of mass optimization and part integration.

Through the know-how earned in over 25 years of activity serving the most demanding and high-performance industrial sectors, CRP Technology has been able to assist LISA and CNES in considering the best additive manufacturing technology and material to guarantee the success of the project.

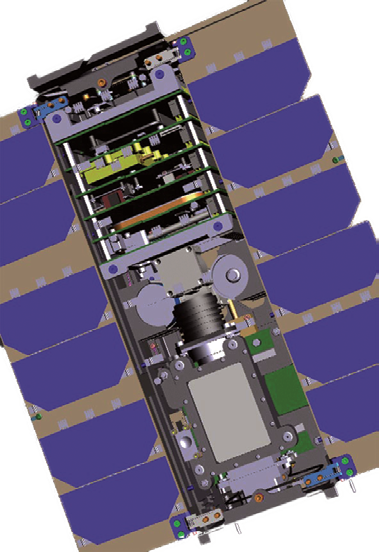

Antenna frame integrated in the 3D

printed structure. Photo is courtesy

of LISA.

The technology and composite material selected for the manufacturing of the 3U cubesat structure were selective laser sintering (SLS) and Windform® XT 2.0. Selective laser sintering (SLS) is an additive manufacturing (or 3D printing as it’s regularly called) process that uses a laser as the power source to sinter powdered material (typically nylon/polyamide), aiming the laser automatically at points in space defined by a 3D model, binding the material together to create a solid structure.

An internal view of the 3U cubesat.

The image is courtesy of LISA

Windform® XT 2.0 replaces the previous formula of Windform® XT in the Windform® TOP-LINE family of composite materials for SLS. Windform® XT 2.0 features improvements in mechanical properties including +8 percent increase in tensile strength, +22 percent in tensile modulus, and a +46 percent increase in elongation at break. These mechanical properties have guaranteed the achievement of the required characteristics, i.e., stiffness, low mass as well as very smooth surface finish.

Once received the .STP file with optimized geometries from LISA, CRP Technology created in a short time the functional 3D printed component (the nano-satellite structure) via selective laser sintering using Windform® XT 2.0.

Professional 3D printing, combined with Windform® XT 2.0 Carbon-composite material, proved to be the best choice: the 3D printed part has successfully passed the control and testing criteria, and has fully complied with the requests and LISA’s standards.

LISA and CNES performed many tests on the 3d printed nano-satellite structure such as vibration tests and thermal-vacuum tests. They were very satisfied with the results obtained.

www.crptechnology.com

Author: Matteo Levoni

Bemposti

The LISA team stated that thanks to CRP’s laser sintering technology and Windform® XT 2.0 Carbon-reinforced composite material, we obtained important key advantages such as mass reduction, component integration, outgassing control, thermal expansion, and low surface roughness.

The team added, “We are more than satisfied with selective laser sintering technique and consider Windform® XT 2.0 one of the disruptive revolutions in the small satellites arena. We do hope to use additive manufacturing intensively in space application.”