CRP Technology, based in Italy, part of the CRP Group, has used their Windform composite materials and Laser Sintering technology to manufacture the 3D printed Tundra-M, the functional prototype of Hexadrone’s first modular, easy-to-use, unmanned aerial system (UAS) drone.

The Tundra-M can turn into a formidably effective and pliable work tool, thanks to the unit’s four quick connect arms as well as three accessory connections. This makes the Tundra-M suitable for a variety of flight scenarios.

The body, as well as the main parts of the UAS, have been implemented with the composite polyamide based material carbon filled Windform® SP and Windform® XT 2.0: the four arms supporting the body frame of the Tundra were 3D printed using Windform® XT 2.0 composite material. The remainder of the components and the body structure were developed with the Windform® SP composite material.

Understanding the limitations with traditional manufacturing technologies, the opportunity to develop a unique drone based on the use of Additive Manufacturing (AM) technologies was identified. AM technologies in UAS applications has presented opportunities and challenges to engineers in the field. The ability to produce parts and components using AM technologies holds promise in metals and plastics, whereas traditional Subtractive Manufacturing technologies can be restrictive in design development and material selection.

Windform® SP has waterproof properties and is resistant to absorption of liquids and moisture, making this technology suitable for dyno testing and on track testing and for applications requiring resistance to impact, vibration, deformation, and high temperatures, such as UAVs, Aerospace and related industries, motorsports and automotive (for under the hood applications such

as manifolds).

Hexadrone CEO Alexandre Labesse said that the company has engineered their drone by means of a cautious, multi-faceted and collaborative approach with the involvement of many broad-based stakeholders. Over the course of two years of consulting and R&D, the company has gathered all of the advice and customers’ testimonials useful to the design process, which finally helped the firm in the process of devising an ideal UAV solution.

AM technology is often faster than designing and producing a tool for use with traditional manufacturing technologies. Furthermore, 3D printing has given engineers more flexibility in the timeline to engage in design improvements and enables them to think outside of the limitations caused by traditional tooling. The decision to use AM made it possible to substantially reduce the manufacturing costs and has been convenient in terms of timing, when compared to traditional production methods. The unique properties of Windform® XT 2.0 and Windform® SP composite materials have allowed system optimization that successfully withstands the necessary design requirements of space limitations and the extreme stress conditions that occur during flights.

“The Windform® selective laser sintering technology,” Alexandre Labesse said, “and allowed us to easily prototype key components of our product, to out compete the plastic injection molding process in terms of deadlines, cost, and to test our prototype in real life conditions with almost the same mechanical characteristic.

“The project we have designed with these two materials, the Windform® SP and the Windform® XT 2.0 from CRP Technology, lies in the conception of different frame parts, junction parts, a quick release patented system as well as the components forming our patented carbon-made arm system. This 3D printing time/cost saving technology helped us a lot and now allows us to calmly approach the mass production phase.”

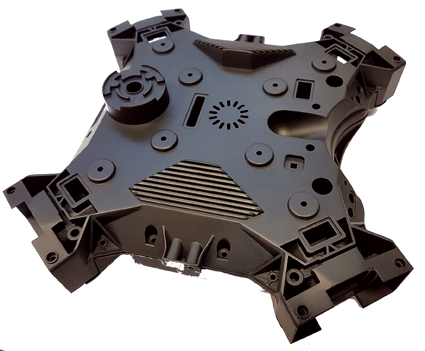

The Tundra body frame.

CRP Technology provided a fast response time to new requirements and enjoyed solid cooperation with Hexadrone and the CAD designer and obtained the best output quality using this unique and proprietary process.

Alexandre Labesse added,“Regarding the most innovative aspect of Laser Sintering technology with Windform® materials, lies in the possibility to prototype with all the pros of the plastic injection process without the cons this method entails in terms of cost and deadlines. Furthermore, Windform® provides us with a close enough material in terms of properties (e.g., density, color, tensile strength, modulus, elongation at break, etc.)”

The most interesting parts that have been made using the Windform® SP and the Windform® XT 2.0 are the body frame, which is composed of the main frame, plus a removable top lid. This component contains the brain of the Tundra-M (the main circuit boards as well as the cooling system).

Labesse continued, “To devise this component, we were in need of a water-resistant, durable and sturdy material. Moreover, this sturdy frame comes with an emergency parachute, four removable and scalable arms, two batteries as well as three easily interfaceable accessories. The Windform® composite material used for the body frame is Windform® SP due to its mechanical and thermal properties.

“Other interesting applications manufactured in Windform composite materials are the arms, which are composed of motor supports plus the removable arms. An interlock base allows the user to easily tighten the four arms with the support of a patented “tension ring. This stiff system permits the user to connect and disconnect the interchangeable arms on a discretionary basis. Our patented technology offers a reliable and sturdy connection while being a waterproof solution in case of inclemency. This interlocking connection is also able to handle the stress of leverage forces, which are primarily generated through the components at the end applying a constant force through masses.”

The Windform® composite material used for the arms is Windform® XT 2.0

The tests Hexadrone carried out included...

• The assembly / disassembly tests of the different parts to road test their structure as well as the fatigue resistance of these new materials

• Landing tests, folding and unfolding the landing foot structure of the Tundra-M drone, whose different structures were made in Windform® • SP and which support the full weight of the Tundra-M. On top of the weight of the device, those small parts also have to handle the stresses due to the folding/unfolding of the landing system

• Flight tests, to determine whether the mounted parts can handle the different strains encountered throughout the many different flight scenarios.

The Windform® Composite Materials

Windform® XT 2.0 and Windform® SP are the LS polyamide-based, carbon fiber reinforced, Windform® materials within the Windform® family of high-performance composite materials.

Windform® XT 2.0 is the ground breaking carbon fiber reinforced composite 3D printing material well-regarded for its mechanical properties and is particularly suitable in demanding applications.

Windform® XT 2.0 is an innovative material that replaces the previous formula of Windform® XT in the Windform® family of materials. Windform® XT 2.0 features improvements in mechanical properties, including +8 percent increase in tensile strength, +22 percent in tensile modulus and a +46 percent increase in elongation at break. The material allows for the creation of accurate, reliable, and durable prototypes and is perfect for functional applications.

Windform® SP has excellent mechanical properties similar to Windform® XT 2.0, with the addition of increased resistance to shock, vibrations and deformation. The material also shows increases in impact strength and elongation at break, as well as excellent thermal properties and resistance to high temperatures.

https://www.crptechnology.com

http://www.windform.com

info@crp-group.com

The author is Matteo Levoni Bemposti of CRP Technologies.