US-based CRP USA manufactured three engineering models for Mini-Cubes. This is the first time that entire flight-ready and functional prototype PocketQubes have been manufactured using a carbon-reinforced composite material — Windform® XT 2.0 — and the Laser Sintering process.

Mini-Cubes, LLC, was founded in 2018 to take the concept of a PocketQube — a super smallsat — and develop it into a viable product. Joe Latrell, the CEO of Mini-Cubes, and his team accomplished this effort on the principle that virtually anyone can reach space today. With PocketQube satellites, they hope to achieve a better grasp on resource monitoring and offer the public a chance to be among the stars.

The Project

Recently, Joseph Latrell and his team started a new project based on a new 1P PocketQube flight-ready, named Discovery. He turned to CRP USA for the manufacture of the entire satellite frame via Additive Manufacturing (AM).

CRP USA is a 3D printing company that is based in Mooresville, North Carolina, and has built considerable experience supplying cutting-edge solutions for key industry leaders in the space market segments using the Laser Sintering process and Windform® TOP-LINE reinforced composite materials, created by Italy-based CRP Technology.

The primary objective of the project was proof of concept for satellites this small. Joe Latrell explained, “We wanted to include a camera for visual observation, again just to see if it could be done. If the process works, we see using the technology to create a constellation of PocketQube satellites just for monitoring a specific resource. In our case that resource is water.”

Joe decided to use professional 3D printing as he has been a fan of AM for some time now. “I first used the process for making prototype rocket fins when I worked at an aerospace company. When we started working on Discovery, I knew I wanted to push the boundaries of what was possible — everything from the small satellite form factor to the technology used to make it. For that reason, I decided to involve CRP USA team and their Director of Operations, Stewart Davis. I knew that with their expertise and experience in the sector, they would be the ultimate technological partner for this important project”

The Challenge

The main challenges were related to the small dimension of the satellite and to the material, as it was the first time that an entire satellite would be built from a carbon-composite material.

Latrell noted, “Discovery is a PocketQube satellite. These are spacecraft that are small in size at 50x 50x 50 mm internal volume. Our particular satellite is a demonstration of what can be done for remote sensing of Earth’s resources on that smaller scale. The challenge with something this small is to fit the electronics, camera, and radio system into it.

The assignment was not simple or easy, as the Windform® parts in the Discovery would be mission critical.

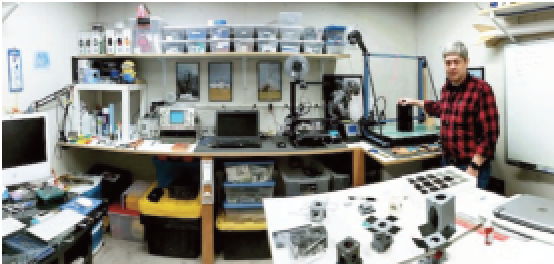

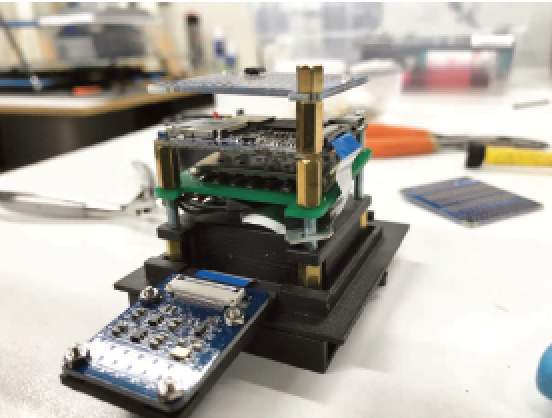

MiniCubes CEO Joe Lattrell at work on the Discovery smallsat. Photo is courtesy of MiniCubes.

MiniCubes CEO Joe Lattrell at work on the Discovery smallsat. Photo is courtesy of MiniCubes.

Computerized Numerically Controlled (CRC) machining in action. Photo is courtesy of CRP USA.

Joe clarified, “This was the first time an entire satellite would be manufactured from a material such as Windform® XT 2.0. Performance was everything. If any one of the parts fail, that would result in complete failure of the spacecraft.”

However, thanks to the long-term experience gained in the field of AM service alongside the key leaders of the most advanced industrial sectors, CRP USA accepted the challenge... and won it.

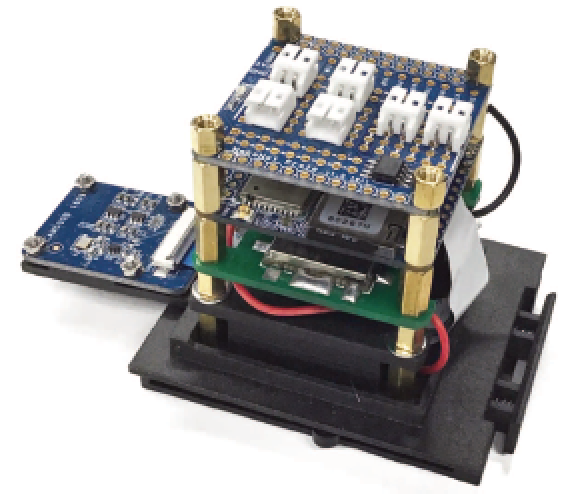

The inner workings of the Discovery 1a engineering model.

Photo is Courtesy of MiniCubes.

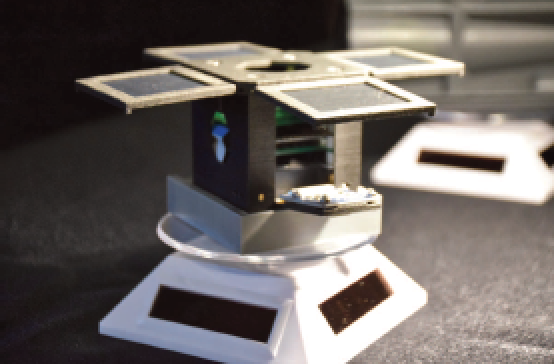

The Discovery 1a engineering model on display at the 3rd PocketQube

workshop in Glasgow, Scotland. Photo is courtesy of MiniCubes

“Joe’s team brings a unique challenge as they are packing a lot in a small package. Our team was able to use our experience with Windform® to help move the project forward,” said Stewart Davis. “Adapting to new and complex applications has become key to CRP USA’s further advancement.”

For the manufacture of Discovery 1a, Latrell and the CRP USA staff decided to use carbon-fiber reinforced Windform® XT 2.0.

“The combination of strength and ease of use made the material a natural choice for us. We knew we wanted to use additive manufacturing for Discovery but understood that it would be hard to find something that would work in the harsh environment of space. We discovered Windform® XT 2.0 and after looking at its properties, it was a simple choice, said Latrell.”

Checking circuit board fit on the engineering model. Photo is courtesy

of MiniCubes

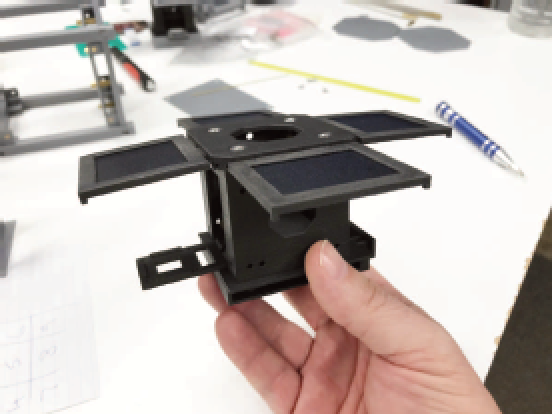

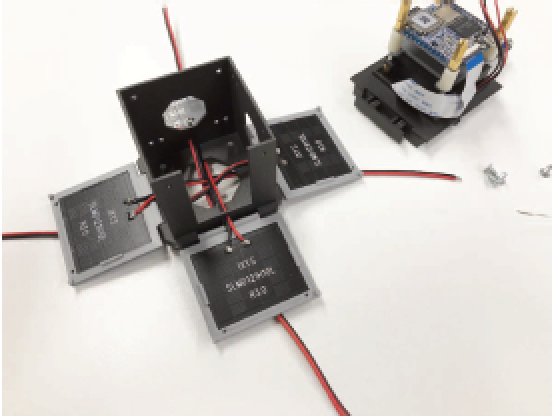

First assembly of the Windform frame Photo is courtesy of MiniCubes

Windform® XT 2.0 replaces the previous formula of Windform® XT in the Windform® TOP-LINE family of composite materials and features improvements in mechanical properties that include an 8+ percent increase in tensile strength, +22 percent in tensile modulus and a +46 percent increase in elongation at break. These mechanical properties have guaranteed the achievement of the required characteristics, i.e., stiffness, low mass as well as very smooth surface finish.

Moreover Windform® XT 2.0 — as mainly composite materials Windform® TOP-LINE — has passed outgassing tests at the most important space agencies and has been found to be highly suitable for space missions.

Result / Testing

Fitting test of the solar arrays to the structure in

Windform XT2.0. Photo is ourtesy of MiniCubes.

CRP USA manufactured for the Mini-Cubes company three, 1P PocketQubes, functional prototypes: two for testing and one for flight.

The CRP USA Laser Sintering process combined with Windform® XT 2.0 carbon-composite material proved to be the best choice: the 3D printed 1P PocketQubes functional prototypes have successfully passed the control and testing criteria and have fully complied with the Mini- Cubes’ standards.

Joe commented, “We have run quite a few tests, with many more on the way. So far, we have load tested to more than 20 kg. The material has been vibration tested to NASA GEVS-7000 specifications, subjected to a near vacuum to simulate the conditions in Earth orbit as well as thermally tested from +50c to -40c. Windform® XT 2.0 has passed every test we threw at it. The next step for us is to test the satellite on-orbit. This will be the final validation for our process. The plan is to launch sometime during Q2 of 2021.”

CRP USA works alongside key space industry leaders and contributes to missions that have marked new milestones in the smallsat arena: PrintSat, KySat-2, TuPOD, AMPS, to cite a few.

“All these projects brought a unique challenge. Our team was able to use our experience with Windform to help move these projects forward. Adapting to new and complex applications has become key to CRP USA’s further advancement,” said Stewart Davis. “Unlike many technologies that were originally developed for Aerospace that are then adapted to Motorsports, Windform XT 2.0 is a purely Motorsports drive material. Indeed, Windform was originally developed by CRP USA’s partner CRP Technology based in Modena, Italy, for use in Formula One Racing, first in the wind tunnel and then on the track. Now Windform XT 2.0 and all the Windform composite materials are used in the most advanced industry sectors, to manufacture complex and harsh final parts and functional prototypes.”

www.crp-usa.net

mini-cubes.com

Author Matteo Levoni Bemposti is an engineer who specializes in Additive Manufacturing and Windform Materials. He is the Head of the Reverse Engineering Department at CRP Technology. He attends international conferences as a speaker on the use of the Additive Manufacturing in different fields, such as as aerospace, motorsports, aviation, automotive, marine and UAVs .During his career, Matteo Levoni has also designed engines for a major automotive manufacturer. He graduated in Mechanical Engineering at the University of Modena and Reggio Emilia. Contact information: info@crpgroup.com