Why Ka-Band TWTAs Come With Their Own Set Of Challenges & Opportunities

Although the past 12 months has been a challenging time for all of us, in both our private and business lives, SpacePath Communications (‘SpacePath’) has been quietly and studiously focused on its Ka-band uplink amplifier design, a high-power, ground-based, TWT (traveling wave tube) which required some new thinking.

Being smaller, lighter and more efficient remain the main development drivers for most amplifiers but in a highly competitive marketplace, customer requirements have also turned to both cost and long-term cost-of-ownership. With the release of our new family of Ka-band high-power amplifiers (HPA), covering commercial and military bands up to 650W of output, we achieved our design objectives which included several key customer-driven features.

SpacePath’s Ka-band amplifiers feature two platform sizes, the STA4000 and STA5000. The STA4000 small enclosure design accommodates amplifiers up to 250W and the slightly larger STA5000 covers higher outputs of 500W (CW), 550W (peak) and 650W (peak), which provide in excess of 220W linear power.

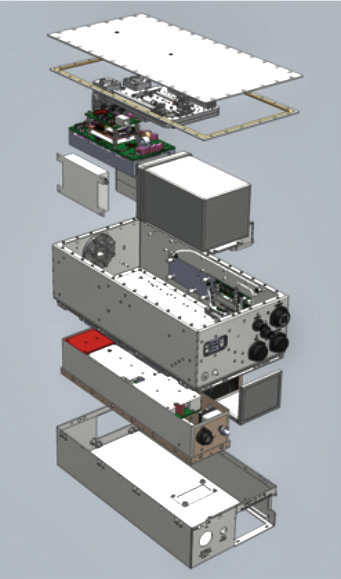

Modular Design

For convenience, these Ka-band units feature a modular construction with many elements common to both the STA4000 and STA5000. This simplified design approach allows for ease of construction, lower parts count and reduced manufacturing lead times.

Common modules include:

AC Module (ACM)

The ACM is a high efficiency AC-DC converter, operating over a broad range of AC input voltages, 100-240 VAC. The ACM incorporates a very high efficiency power factor correction circuit and soft-start circuits to ensure reliable and robust operation under normal operating conditions, as well as soft and hard power outage conditions. The ACM is designed and qualified with margin and integrity, to support all levels of power delivery for amplifiers up to 1,500W of RF power.

TWT Power Supply

The proprietary TWT power supply operates from the rectified output of the ACM and employs the latest resonant conversion techniques to provide all the bias voltages required by the TWT. The resonant design also ensures high efficiency and low EMI emissions.

Fan Module (FM)

The FM module provides bias and controls for the cooling system. The module is the same for all product platforms.

RF Module (RFM)

The RFM provides bias and controls for RF devices, including SSA, linearizer, BUC, detectors, limiters, etc. The RFM is the same for all product platforms, designed to accommodate various RF components.

Holistic Layout

Another key design objective behind the development of these new amplifiers was to minimize their size and weight. Achieving this has resulted in products that are typically 15 percent smaller and 30 percent lighter than comparative devices. The reduction in size has been achieved through the use of the latest solid modeling techniques and a holistic approach to the mechanical layout.

An exploded view of a SpacePath amp.

Starting with the major components, the TWT and cooling fan were positioned and used to determine the overall amplifier proportions. Areas were then allocated to the various modules making sure that the space was practical to achieve the required design parameters. Additionally, the requirements for ease of assembly and maintenance were determined while also ensuring modules could be compatible in either the STA4000 or STA5000 chassis.

Innovative techniques have been used to realize the required module sizes, such as the TWT power supply. This assembly, which provides up to 25 kV, enables the same module concept to be used throughout the amplifier range including the highest to be used throughout the amplifier range includin voltage TWTs, including Q/V-band future designs.

The reduced weight of the amplifiers is due mainly to SpacePath’s pioneering use of carbon fin technology in the cooling system, replacing the traditional copper fins used for the TWT heat sink.

These carbon fins are typically 80 percent lighter than their copper equivalent, and a speed-controlled, high performance, centrifugal fan also ensures that the TWT temperature is maintained within the safe operating limits.

Ka-band devices also come with their own set of specific design challenges. The amplifiers operate at much higher voltages, the power supply needs to be extremely robust, and the control systems must be capable of rapidly controlling the power supplies to protect the high value TWTs (compared with lower band tubes) which can be more easily damaged by voltage anomalies. Therefore, another key design driver was to improve amplifier reliability and thereby reduce the long-term cost-of-ownership for the end-user.

This goal was achieved by protecting the TWT, the highest value component within the amplifier, through the precise control and operation of the TWT via the power supply. Integrated protection circuitry is able to sense and prevent damage of the TWT due to misuse or mishandling of the HPA.

For example, the energy storage of a power supply has to be appropriately aligned to the TWT’s needs. Storing energy is easy, however storing too much is undesirable and can be problematic if not managed during on/off switching of the TWT, especially during fault-generated turn-off conditions. The higher the frequency of the TWT, the lower the energy storage must be to prevent damage.

This is a relationship directly proportional with the size of the RF circuit. As a result, precautions need to be taken in the TWT power supply to limit the stored energy.

For TWTs in the millimeter wave bands (Ka- and above) additional controls are provided with the amplifiers, which when used appropriately, further mitigate the risk of damage due to energy dispersion into the circuit of the TWT during turn-on and turn-off conditions.

The common practice with lower frequency TWTs in the microwave regime is to ‘cathode switch’ the beam, meaning to apply all operating voltages simultaneously. The amplifier’s RF circuits are physically larger and so can tolerate increased amounts of energy dispersion during such switching.

SpacePath’s STA4000 series TWTA.

Millimeter wave TWTs of high reliability design often have extra control voltages that enable more precise management of the electron beam switching. Cathode switching on millimeter wave TWTs is, therefore, a common practice, but extra attention and care to the operation of the TWT by use of the control anode is required to mitigate the risk of unnecessary power supply energy dispersion in the RF circuit during switching.

The core of the TWT operating voltages is switched on simultaneously, with the exception of the control anode, which is independently controlled. Through independent control and timing, the energy dispersion can therefore be managed.

TWTs are intrinsically robust devices and millimeter wave TWTs have outstanding, proven reliability. However, like all RF devices, if they are not properly handled and operated, they can be subject to damage.

In particular, the operation and protection of TWTs when integrated with a power supply, cooling system and control system in an HPA is critical to their longevity and reliability. Some engineering can prematurely shorten the life of a device or cause irreversible damage but with meticulous attention and care in design and manufacture, high-power TWT amplifiers can ensure many years of reliable operation.

Customer-Driven Industry Firsts

SpacePath continues to be driven by a deep understanding of customer requirements. As such, the company’s new Ka-band outdoor, high-power, traveling wave tube (TWT) amplifiers typify this approach by incorporating many new practical and cost-effective user features.

From an industry first, using a carbon-based air-cooling structure that possesses similar thermal properties to copper at half the weight, to innovations such as removable air filters for easy maintenance and a convenient front-panel monitoring display, SpacePath’s ongoing R&D is committed to advancing HPA design, all in line with the evolving and increasingly demanding, technology-driven, market segments.

www.space-path.com

Author Terry Hall is the Engineering Manager at SpacePath Communications.