Space Flight Laboratory’s Flex Production enables flexibility for New Space companies

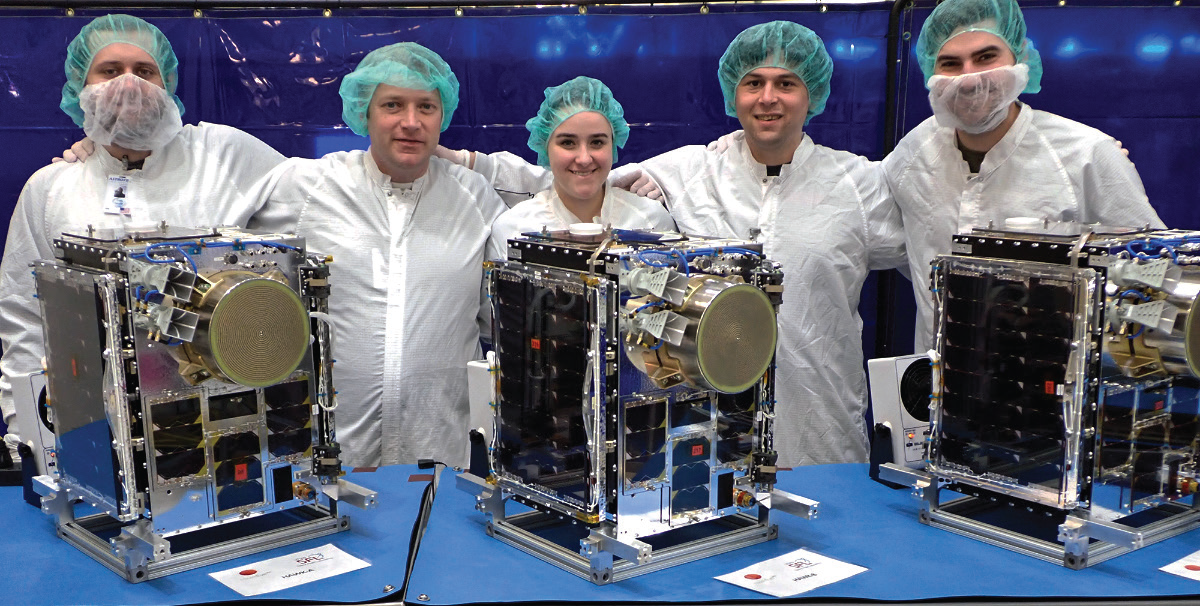

The April 2023 launch of HawkEye 360’s seventh cluster of radio frequency (RF) geolocation smallsats highlighted a unique collaboration of Microspace and New Space business models. The three Cluster 7 spacecraft were the first integrated and tested at HawkEye 360’s new manufacturing facility in Virginia under Space Flight Laboratory’s (SFL) Flex Production program.

The three Cluster 7 spacecraft were the first integrated and tested at HawkEye 360’s new manufacturing facility in Virginia under SFL’s Flex Production program. Photo Credit HawkEye 360.

Toronto-based SFL designed and built the previous six clusters in Canada, all of which were launched and operate successfully today. Starting with Cluster 7, however, SFL assembled the satellite units, based on the company’s popular 30 kg.... DEFIANT smallsat bus and shipped them to the HawkEye 360 plant. There, the U.S. company’s personnel handled integration of the spacecraft with the RF signal tracking payload — with technical guidance provided by SFL.

HawkEye 360 was an early adopter of the hybrid satellite development process that SFL created to accommodate evolving business models in aerospace, especially among New Space ventures. For HawkEye 360, the hybrid manufacturing approach is a winning combination — the company recently extended the production contract with SFL, building Clusters 12 and 13 in Herndon, Virginia.

“Clusters 12 and 13 continue our long-standing relationship with Space Flight Laboratory,” said Rob Rainhart, COO. “[SFL Director] Dr. Zee and his team have been excellent technology partners, providing us the means to build reliable satellite buses with proven heritage. We’ve enjoyed being early customers for their Flex program.”

HawkEye 360 originally selected SFL to build the first Pathfinder Cluster in 2018 due to SFL’s space-proven formation flying technology for multiple satellites in orbit — a crucial capability for terrestrial RF signal geolocation from space. Based on Pathfinder’s success, SFL continued to develop smallsats for HawkEye 360, which has cemented its position as the undisputed global leader of RF detection and analysis for maritime situational awareness, emergency response, national security, and spectrum mapping applications.

“Flex Production gives our New Space clients the best of both worlds by leveraging our Microspace expertise while meeting the competitive financial requirements of their commercial business models,” said SFL Director, Dr. Robert E. Zee.

New Space Competition Demands Technology Enhancements

Celebrating its 25th anniversary this year, SFL is a unique smallsat provider that offers a full lineup of high-performance, low-cost small-, micro-, and nanosatellites (including CubeSats), covering a wide range of mission types from 3 to 500 kg..... With 65 operational successes (as of June 2023), SFL’s missions are known for their extraordinary attitude control and formation flying as well as modular power system technologies at affordable price points.

“Early on, we implemented the Microspace approach to satellite development combined with an emphasis on state-of-the-art design, the right technology for the mission, innovative processes, and thorough testing,” said Zee. “The result has been sophisticated microspace missions completed in less time and at a fraction of the cost normally associated with high-quality satellites – satellites that actually deliver what they promise.”

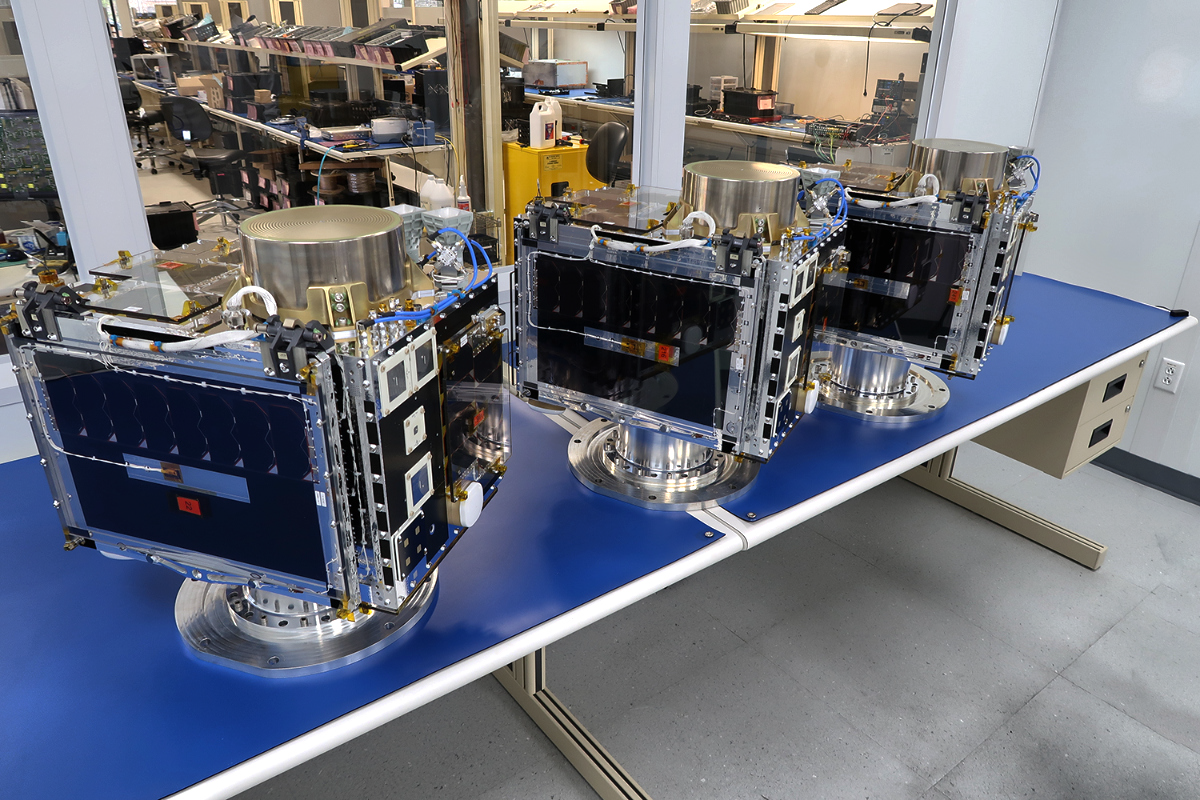

HawkEye 360’s seventh cluster of smallsats joins a successful constellation that detects and geolocates radio frequency (RF) signals for maritime situational awareness, emergency response, national security, and spectrum analysis applications worldwide. Photo Credit HawkEye 360.

SFL built its business on comprehensive mission development, delivering services from design conceptualization through spacecraft manufacture. If requested, the SFL team also assists clients in arranging launch services and setting up ground stations and/or mission control facilities.

As the New Space era has matured, SFL saw an opportunity to modify the organization’s end-to-end service offerings with production options to support that sector’s increasingly competitive economics.

Flex Production enables clients to tap into SFL’s expertise

and 25-year legacy of success. Photo Credit HawkEye 360.

New Space companies are vertically integrated from top to bottom, explained Zee. Their primary business objective is typically to collect data, analyze the data, or extract information from the data and sell data products. Satellites are the tools they use to create these products and services. To control costs, they usually maintains every aspect of their business in-house — from building and operating their satellites to analyzing the data and selling to customers.

“Like any commercial organization, a New Space company seeks to maximize the efficiency of the value chain to reduce costs — and for many, that means building their own satellites, especially where mass production fosters economies of scale,” said Zee. “But what if there was a way to satisfy New Space economics while also benefiting from SFL expertise in spacecraft development? Always looking for a better way to serve our potential customers, we decided to offer customized production options to help minimize the New Space cost base and make their business models more viable while leveraging SFL’s strengths in design, innovation and heritage.”

Hence, SFL rolled out the Flex Production program with a variety of manufacturing alternatives to meet different economic demands. Improving the New Space client’s finances, however, is just one benefit of the SFL offering.

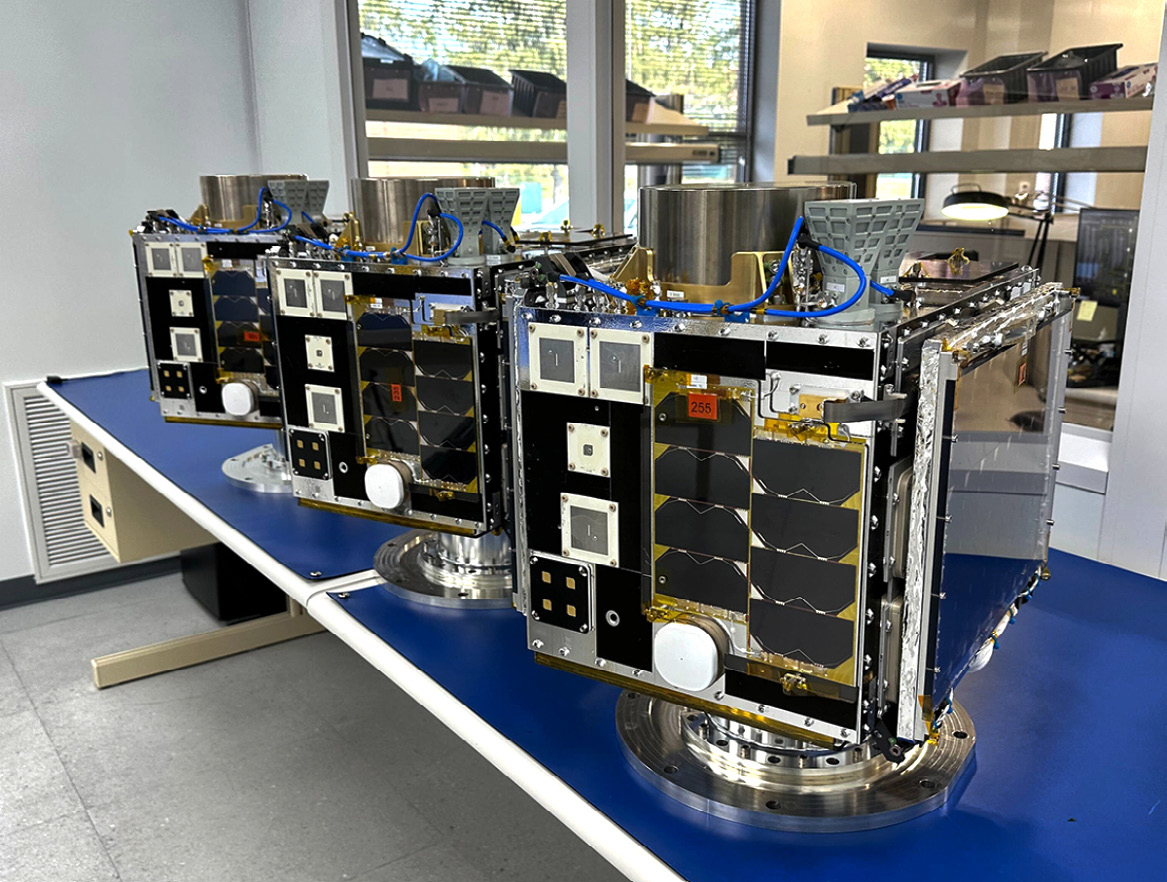

The Flex Production program delivers significant cost savings

when many satellites are being manufactured.

Photo Credit HawkEye 360.

“The challenge for commercial New Space companies is keeping up with their competition by constantly upgrading their products and services,” said Zee. “More often than not, this means continually enhancing their satellites. But that requires maintaining intense and continuing expertise in spacecraft development which is a separate business model entirely. That’s where SFL comes in.”

Zee further elaborated and stated that New Space companies can affordably hire a staff of technicians to assemble, integrate, and test satellites in an integrated workflow. However, the need to change spacecraft design quickly and effectively and implement newer technologies is a different challenge and area of specialty. If the latter is to succeed, it requires an experienced team of engineers that is dedicated to spacecraft development for the company to remain competitive.

“For most New Space companies, it’s simply not cost effective to maintain a ‘company within a company.’ Either you are good at selling data, or you are good at designing reliable spacecraft — it’s not easy to do both well,” said Zee. “Developing new, cost-effective satellites that work the first time is our specialty at SFL — it’s what we do, and we do it for many different applications, missions and customers, year after year. Flex Production enables clients to tap into our powerhouse expertise and 25 year legacy of success, while still benefiting from New Space economics — yes, the best of both worlds.”

Flexible Manufacturing Options For New Space Needs

To accommodate the various financial requirements and technical capabilities of clients interested in manufacturing some or all of its satellites in house, SFL has established four levels of service in the Flex Production program. Each level can be further customized to meet specific client parameters.

HawkEye 360’s Cluster 7 is built on SFL’s space-proven

30 kg. DEFIANT smallsat bus. Photo Credit HawkEye 360.

Production Essential — This is the traditional approach to satellite manufacturing where SFL designs and builds the first spacecraft and all follow-on satellites. Many missions developed by SFL have followed this approach. Its economics are beneficial for single-satellite missions and small constellations. For larger constellations and higher cadence, economies of scale may apply, and one of the next three options may yield cost savings.

Production Plus — In this option, SFL designs and builds the first satellite but then licenses mass production of additional spacecraft to a trusted third party. SFL has forged relationships with aerospace manufacturers capable of performing the required work at facilities set up for rapid production of satellites at high cadence.

Production Assist — SFL designs and builds to completion the prototype satellite, or first several, for the client. From there, SFL assembles only the spacecraft platforms and ships them to the client location where payload integration and final testing are carried out. As needed, SFL provides technical consulting throughout the process as satellites are integrated and prepared for launch.

Production Max — As indicated before, SFL handles design and construction of the first satellite based on its heritage platform technology and then transfers the platform and spacecraft integration responsibility to the client. SFL provides the spacecraft components and units to the client for assembly, integration, and testing. When a large number of satellites are being built (and possibly also at a high cadence), the cost savings in mass production are significant. HawkEye 360 and a Canadian telecommunications company have successfully leveraged the Production Max approach.

“It can’t be stressed enough that each of these production options is flexible, leaving the door open for the client to ask SFL to step in and upgrade the satellite design or system technology at any time,” said Zee.

At the end of the day, he concluded, this enables the New Space company to focus on their primary business objective, which is selling products and services, while SFL focuses on its business goal, which is developing high- performance, low-cost satellites. The overall result is the New Space client can remain confident that their assets in space are of the highest quality and reliability while maximizing returns from New Space economics.

www.utias-sfl.net/flex-production

Author Kevin Corbley is a business consultant based in Fort Collins, Colorado.