Carl Campbell, Vice President of Mission Management, SEOPS

In the intricate world of space missions, satellite deployment is often considered the “easy part” after years of design, development, and launch preparation. But anyone who has worked on spacecraft integration knows that this stage—particularly the separation system—can make or break a mission.

The separation system is the last mechanical interface between a satellite and the launch vehicle, and the first element to act once a spacecraft reaches orbit. It is the moment of truth: the satellite must cleanly release, without imparting unintended forces, vibrations, or debris that could compromise its performance or endanger nearby payloads.

Yet, despite being a critical path item, separation systems are often among the most complex, bespoke, and risk-prone components in satellite integration. For integration engineers, managing that complexity can be a major headache.

SEOPS developed the Keystone Payload Separation Systet with one clear goal: to take the complexity out of satellite release. By providing a simple, strong, and low shock solution, Keystone is helping engineers reduce integration risk, save time, and achieve more predictable mission outcomes.

__________________________________________

The Challenge:

Complexity Hidden in Plain Sight

__________________________________________

Separation systems sound simple on paper. They attach a payload to a launch vehicle, hold it firmly during ascent, and then release it on command once in orbit. But in practice, they sit at the intersection of multiple demanding requirements:

High loads during launch: The system must secure the payload through intense vibration, shock, and acoustic forces during liftoff.

Precision timing: Separation must occur at exactly the correct moment—sometimes within milliseconds—coordinated with other spacecraft deployments.

____________________________

Separation is the final step

before a satellite becomes

operational—and the last

place you want surprises.

Clean, low shock release: The satellite must separate with no residual forces or rotational momentum that could alter its orbit or attitude.

No debris or contamination: Even tiny fragments or residue can jeopardize nearby spacecraft or sensitive optics.

These constraints drive a trend toward increasingly sophisticated separation mechanisms—multi-bolt systems, complex pyrotechnic devices, frangible joints, and intricate release ring assemblies. While technically impressive, they also introduce a range of challenges for integration engineers:

Complex interfaces: Many systems require custom adapters, harnesses, or modifications for each payload geometry.

High part counts: More components mean more potential failure points and more verification steps.

Long lead times: Complex mechanisms can take months to procure and integrate, squeezing already-tight launch schedules.

Difficult testing: Replicating flight conditions for separation verification often requires costly and time-intensive testing campaigns.

In an era when space missions are becoming smaller, faster, and more frequent, this complexity is increasingly at odds with the industry’s needs. Launch providers and satellite operators alike are seeking more standardized, “plug-and-play” approaches to satellite integration.

_______________________________

The Keystone Approach:

Simplicity by Design

_______________________________

Keystone was born from SEOPS’ experience as a mission integrator. Our team has worked hands-on with dozens of payloads from cubesats to large sats, often under challenging timelines and with demanding interface constraints. Over time, one pattern became clear: most separation systems were engineered for extremes, not efficiency. Integration teams were spending disproportionate effort on what should be a straightforward step.

With Keystone, we set out to flip that paradigm. Instead of layering complexity onto the system, we designed it from the ground up for simplicity and reliability.

___________________________

Key design principles

___________________________

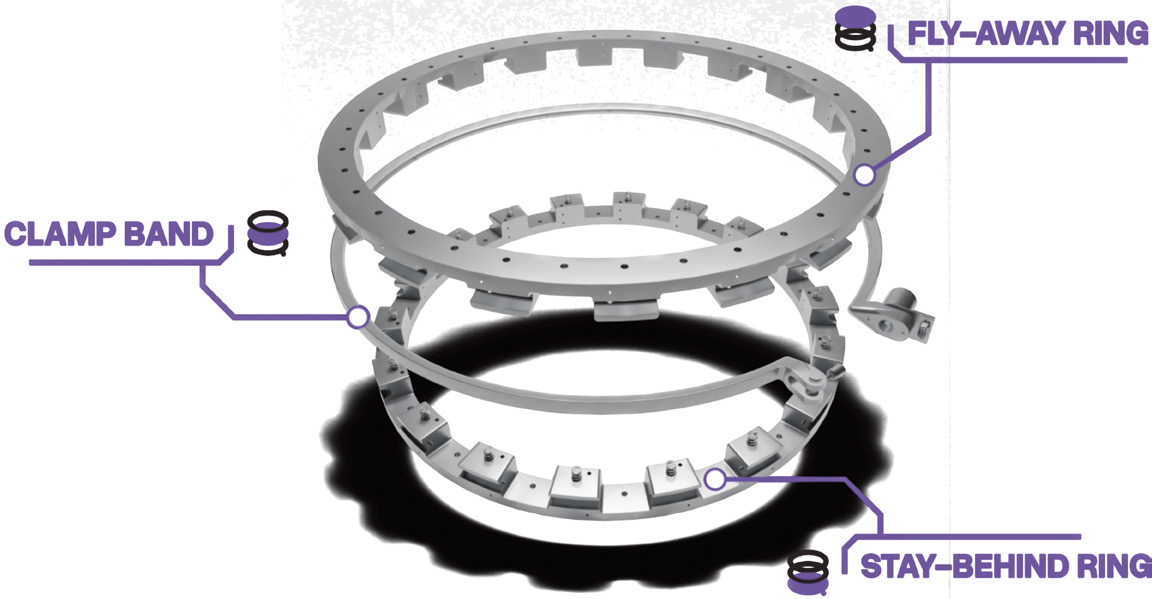

Low part count

Keystone’s minimalist mechanical design uses far fewer components (only three) than traditional separation systems. Fewer parts means fewer interfaces to model, fewer fasteners to torque, and fewer potential failure modes. It’s the first separation system fully tested to launch vehicle flight levels, ensuring launch vehicle providers won’t need to accommodate untested risks. (Side note: The flat rings are CNC-machined from aerospace-grade aluminum alloy, chosen for its strength-to-weight ratio and resistance to deformation under load. Unlike thinner or more delicate rings, Keystone’s geometry resists torque and warping, making it suitable for payloads up to 850 kg.)

____________________________

By stripping away unnecessary

complexity, Keystone makes

satellite integration faster,

safer, and more predictable.”

Exceptional structural performance

While most high-mass satellites require a four-point separation signal—often triggering additional costs from the launch provider—Keystone’s structural strength allows these payloads to fly using a single-interface solution, regardless if your payload mass is 80 kg or 850 kg.

Compact form factor

Keystone measures only 2.10” in height with precision-engineered separation springs which provide smooth, even payload deployment with minimal shock and low tip-off rates. Its small compact size and low mass are ideal for smallsat missions, where every gram and every cubic centimeter counts.

These design choices make Keystone intuitive to use for integration engineers. Installation is quick, inspection is straightforward, and verification can often be done with simple functional checks rather than complex dynamic tests. In short, Keystone is a system engineers can trust—and understand—at a glance.

_____________________________________

Easing the Integration Burden

_____________________________________

Integration engineers are, by necessity, risk managers. Our job is to make sure that dozens of subsystems from multiple vendors come together into a single flight-ready spacecraft stack. Every additional interface is another possible failure point, and every complex mechanism is another item on an already long critical path.

Keystone directly reduces that burden in three ways:

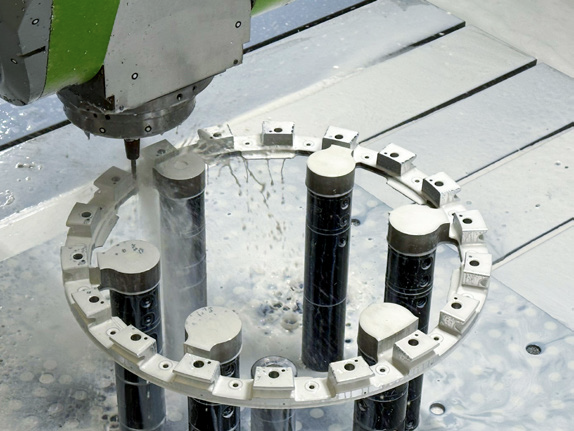

Photo of AJG Aerospace manufacturing the

SEOPS separation system, courtesy of the company

1. Faster turnaround: With its simple design and standard interfaces, Keystone can often be installed and qualified in days rather than weeks. This accelerates mission timelines and provides more schedule margin for other tasks.

2. Lower risk: The low part count and non-pyrotechnic design reduce the number of failure modes that must be analyzed and tested. That translates into fewer “unknown unknowns” late in the integration process.

3. Simplified logistics: With sizes available in 8”, 15”, 24” and 31.6” ring configurations, and lead times as short as two months, Keystone is engineered to meet — and often exceed — the most rigorous Launch Vehicle Provider (LVP) standards. This gives mission planners more flexibility to swap payloads or reconfigure launch manifests on short notice.

4. Reduced costs: Cost matters more than ever in satellite separation systems. As launch cadence accelerates and satellite programs seek faster turnaround, integration teams are under pressure to control costs without compromising mission assurance. SEOPS’ Keystone separation system is manufactured in the U.S. by industry veteran AJG Aerospace, and offers a more economical alternative—delivering high-precision performance at a fraction of the cost. For integration teams working on rideshare launches, where multiple payloads from different organizations must be integrated in parallel, these benefits are particularly valuable.

Keystone helps transform satellite deployment from a bespoke engineering project into a repeatable process.

________________________________

Enabling Enabling

the Future of Space Access

________________________________

As the space industry continues its rapid growth, the number of satellites launched each year is projected to climb into the tens of thousands. That growth depends not only on launch vehicles, but also on the infrastructure that enables satellites to get to orbit safely and efficiently.

Separation systems are a small but crucial part of that ecosystem.By stripping away unnecessary complexity, Keystone offers a path toward more scalable, predictable, and cost-effective satellite integration. It gives integration engineers the confidence that the final, critical step of their work will be as simple as possible—and as reliable as it must be.

For an industry racing to make space more accessible, that kind of elegant simplicity isn’t just convenient. It’s essential.

Author Carl Campbell is Vice President of Mission Management at SEOPS, leading satellite integration and launch operations worldwide. He has overseen more than 200 payloads on over 100 missions. Campbell’s career spans the U.S. Air Force, McDonnell Douglas, Boeing, and 13 years at ULA managing payload interface and separation for Delta II, Delta IV, and Atlas V rockets. He later guided Rocket Lab’s first 20 missions and supported ABL and Virgin Orbit. Now at SEOPS, Campbell applies decades of integration expertise to help customers achieve mission success.

About SEOPS: SEOPS provides innovative spaceflight hardware and launch services to make access to orbit simpler, faster, and more flexible. From launch integration and rideshare management to in-space deployment solutions, SEOPS is focused on enabling mission success for customers around the world. Keystone is the latest example of our commitment to simplifying space.

seops.space