These two professionals recently offered some thoughts regarding Airbus Defence and Space’s upcoming ExoMars mission and the work involved in atmospheric re-entry and heat protection systems for this mission in a mini-interview published at the company’s infosite.

Aurélien Pisseloup heads up the advanced projects and orbital services in the ‘Orbital Systems and Exploration’ business division. Yann Mignot leads the Protection Materials and Advanced Processes Department. Both work at the Airbus Defence and Space site at St-Médard-en-Jalles, where atmospheric re-entry and heat protection systems are developed and built.

Aurélien Pisseloup: The Exomars Missions

ExoMars comprises two missions, one in 2016, the other in 2018. In 2016, the Schiaparelli capsule will re-enter the Martian atmosphere carrying a lander and electronic equipment. The capsule will be launched atop the Trace Gas Orbiter (TGO) satellite on January 7, 2016, on a Russian Proton launcher. The TGO will remain in orbit for two years to act as a telecommunications relay for the second mission, which will be run by the Russian space agency, Roscosmos, and will entail sending a probe to deliver the European Mars rover, developed by Airbus Defence and Space.

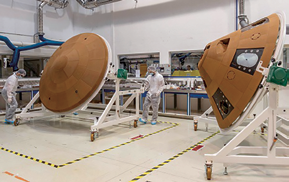

Last July, we delivered the heat shields to Thales Alenia Space, prime contractor for the program, on behalf of the European Space Agency (ESA). These shields are designed to protect the Schiaparelli capsule during re-entry into the Martian atmosphere. Needless to say, these are key elements of the mission. We were responsible for the heat shield—structure, thermal protection and instrumentation—as well as the thermal protection and some of the atmospheric re-entry instruments for the rear shield, with the structure having been designed and built by Thales Alenia Space France.

Yann Mignot: Post-Delivery Support Until Final Assembly

After delivery we intervene, as and when needed until launch, during the flight model assembly, integration and testing. For example, last October, we spent two weeks at the Thales Alenia Space site to integrate the SLI insulation designed to protect the outside of the probe during the nine month cruise through space.

We will then be called upon after the test campaign when the probe and satellite are disassembled and sent to Russia in mid-2015. Thereafter, we will be involved during the final assembly campaign in Russia in late 2015. This will entail assembling the final heat shield elements, for example, once the fuel tank doors have been closed.

The thermal protection tiles are made of a material which absorbs some of the energy it receives by losing thickness when subjected to the extremely high heat caused by kinetic heating during the re-entry through the Martian atmosphere. This highly insulating material is affixed to large surface areas using a silicon glue.

When the project started, there were no plans for Airbus Defence and Space to handle this activity. However, as the project progressed, it became clear to the customer that assembly of the heat shields could not be left to chance and that our know-how was the valuable legacy of a long line of previous projects.

Aurélien Pisseloup: One Successful Challenge…

All the teams involved successfully met the challenge, which was to deliver a product compliant with the time, quality and cost requirements of our customer in a complex industrial context: four partners—Thales Alenia Space France, Thales Alenia Space Italia, Airbus Defence and Space France and Airbus Defence and Space Spain—are all linked to the Europe-wide nature of ESA.

The mission is not over, but we are already eagerly looking ahead to the next step: a Martian sample return mission. In technical terms, we are ready. We are capable of ensuring entry into the Martian atmosphere and the return voyage with re-entry to Earth.

ExoMars is not yet a success, but we must take advantage of this wonderful experience immediately, to avoid having to relearn in the future what we already know how to accomplish today.

The Airbus Defense and Space ExoMars infosite: http://www.space-airbusds.com/en/programme/exomars-l95.html