Orbit Fab and Benchmark Space Systems Team to Establish In-Space, High-Test, Peroxide-based Refueling, Servicing Infrastructure

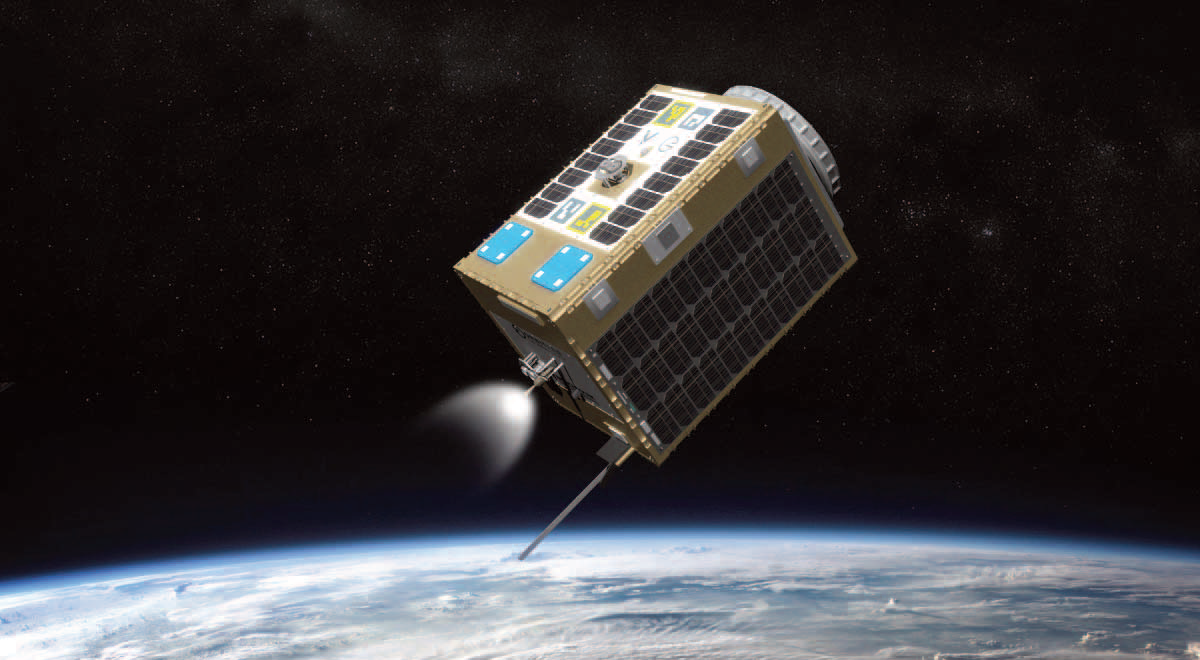

As part of the teaming, Orbit Fab will bundle their RAFTI fluid transfer interface with Benchmark’s Halcyon thruster system to offer an integrated refillable, nontoxic propulsion package. The innovative refueling solution is set for a technical demonstration at the SpaceX launch pad and in space aboard Orbit Fab’s first operational fuel depot to be lifted into orbit on a Falcon 9 later this year.

Orbit Fab, the Gas Stations in Space™ company,

and Benchmark Space Systems (BSS), a provider

of inspace mobility solutions, announced a green,

hydrogenperoxidebased refueling and servicing

infrastructure partnership to extend satellite

missions and provide the essential fuel for the

evolving ecosystem in space.

Benchmark Space Systems will use Orbit Fab’s Satellite Gas Cap™ fluid transfer interface, known as RAFTI, to fuel Orbit Fab’s Tanker001 Tenzing on the ground. Benchmark will also offer the RAFTI interface as an option with its Halcyon and Peregrine propulsion solutions for onorbit refueling.

Benchmark recently announced an exclusive services agreement with Spaceflight to provide a full range of nontoxic chemical propulsion solutions designed to accelerate satellite rideshare deployments to prime orbital locations aboard the firm’s nextgeneration Sherpa OTVs.

Astro Digital is integrating Orbit Fab’s fuel tanker — including Benchmark 's Halcyon system — for positioning and steering along with other customer payloads being hosted by Astro Digital on an AD Corvus Micro Satellite bus launching to Sun Synchronous Orbit (SSO). Orbit Fab intends to operate many satellite tankers with HTP and has agreed to use Benchmark as their propulsion system provider for these future missions.

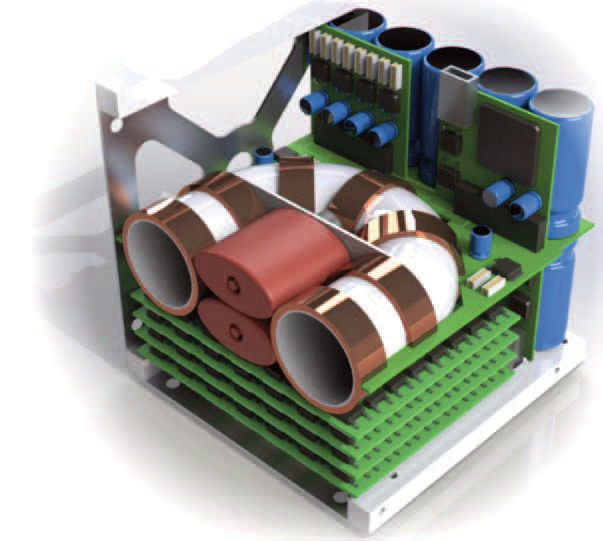

Orbit Fab will bundle its RAFTI fluid

transfer interface with Benchmark’s

Halcyon thruster system to offer an

integrated refillable, nontoxic propulsion

package (image credit: Bryan

Versteeg/Spacehabs.com)

Orbit Fab’s Tanker001 Tenzing will store HTP propellant in SSO where it will be available to satellite servicing vehicles and other spacecraft as they need to be refueled. Hydrogen peroxide is an environmentally friendly and costeffective fuel that is particularly effective for inspace thrust and maneuverability.

When compared to electric propulsion systems, nontoxic chemical propulsion, such as HTPbased systems, deliver spacecraft to their orbital locations much faster.

“We expect the bundled hightest peroxidebased propulsion package will become an essential building block for the inorbit ecosystem for satellite servicing, national security, and space commercialization,” said Daniel Faber, CEO of Orbit Fab. “Together with Benchmark Space Systems, we share a longterm perspective and commitment in order to establish a sustainable inspace infrastructure that enables spacecraft to ‘maneuver without regret.’ And we benefit tremendously from the maturity of the Benchmark propulsion system, which is already flight qualified.”

“Our nontoxic, hydrogenperoxide fueled propulsion systems provide the thrust levels, precision and control required for a broad range of rendezvous and proximity operations (RPO), and our integration with Orbit Fab’s RAFTI fuel port opens the door to a safe, sustainable infrastructure for inspace mobility,” said Ryan McDevitt, Benchmark Space Systems CEO. “Spaceflight Inc.’s Sherpa Orbital Transfer Vehicle is a great example of the immediate and fielded customer base we see for Orbit Fab’s refueling depots and our HTP propulsion package that opens the door to an exciting new ecosystem in space.”

FACT.MR Reports That All Electric Satellites are Witnessing a Promising Uptake Across Globe

Currently, the regional segment of North America holds the most considerable share in the global allelectric satellite market. The presence of notable space organizations such as National Aeronautics and Space Administration (NASA) is a key driving factor behind such growth.

Nonetheless, with the increasing demand for communication services in the APAC, it is anticipated that the region will increase investments in communication satellites during the forecast period and will exhibit a highly promising growth rate. Countries such as India, China and Japan, among others, account for the majority of the demand for sectors such as military and commercial communication. This is due to government promotional policies to make their aeronautical, maritime and military industries healthier.

Allelectric satellites are increasingly becoming the solution of choice for propulsion systems on board many types of satellite platforms over the last few years. The most notable indication of this phenomenon is the evergrowing inclusion of allelectric satellites for telecommunication systems, which is fueling both increased demand for existing electric propulsion systems and the production of new components.

The industry is expected to see many more operators choosing allelectric satellite solutions as part of their future and current missions, with the prospect of low weight and longer mission lives attracting the operator’s attention.

Electric propulsion’s appeal is its ability to drastically lower a spacecraft’s wet mass, or the mass of the spacecraft and its propellant, because of the lowmass (and volume) of electric propellants. Compared to chemical propulsion, an allelectric satellite can weigh 50 percent less. Satellite operators can use that free space to pack more payloads on the spacecraft bus, or shrink the satellite for a lowercost launch.

They produce more drag in some cases, certainly for thrusters versus, say, pure ion thrusters. They can also engender erosion of surface materials, which likewise would put deposits on your spacecraft surfaces. They also have potential electrodynamic interference effects that all have to be accounted for, and likewise they are also very expensive compared to a heritage chemical system. However, even with all those features, they have become quite a key offering now among many satellite prime contractors.

The commercial communication application segment holds a notable share of more than 30 percent in the global allelectric satellite market. With the increasing demand for satellite oriented services such as inflight connectivity, seafaring broadband services along with growth in the telecommunications sector, the demand for allelectric satellites in the commercial communication segment is anticipated to be the highest.

The introduction of emerging technologies such as reconfigurable onboard processors (onboard digital processing payloads) and onboard switching techniques is expected to further improve satellite communication with allelectric satellite technology and protocol implementations.

The global allelectric satellite market is consolidated in nature with a few industry giants such as Airbus SE, The Boeing Company and Ariane Group acquiring the top shares. Allelectric satellites are expected to perform exceptionally well with respect to being economic.

Allelectric satellite manufacturers are now trying to figure out how to maximize their share of the electric propulsion market, while not ignoring more conventional customers. Nevertheless, the allure of economies of scale and less reliance on foreign suppliers in the allelectric satellite industry makes vertical integration difficult to bear.

Obtain a sample copy of this report via this link...

Removing the Growing Pain

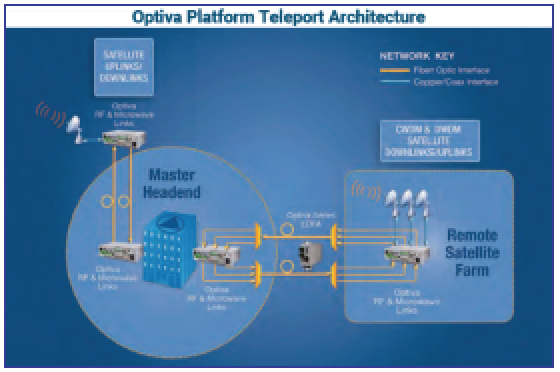

As the requirement for more centralization within teleports continues to grow and the pressure to reduce operational cost increases, more and more companies are looking at fiber optics as an alternate solution to RF over coax/copper to connect their Remote Antenna Farm to their Central Operations Room.

Although the benefits are quite tangible, justification of this capital investment must be made and, as such, making a system that is completely scalable over time is a critical consideration. Emcore has developed their Optiva Platform to address such concerns and allow fiber network architecture to grow seamlessly as requirements grow.

Being in business for more than 30 years, EMCORE has their own, inhouse, laser fabrication facility to build the fiber optic transmitters and receivers from scratch. The company provides a massive range of frequency options for a network.

Emcore's family of Optiva SNMP managed products provides highperformance fiber optic transmission from 1 MHz to 60 GHz.

Frequency Band Options

• LBAND: The most cost-effective entry point in the industry with our new budget L-Band cards operating from 5 MHz to 3 GHz.

• DUAL LBAND: Where chassis space is limited, we can double the number of links with our two-channel card. This can provide up to 30 L-Band links in one 3RU rack.

• 6.5 GHz & 8.5 GHz: A new budget 6.5 GHz card allowing us to carry 5G signals and C-Band traffic at a similar cost of traditional L-Band links. We are also looking to extend the capabilities of this card to 8.5 GHz to serve the military X-Band market.

• DEDICATED SATELLITE BANDS: Dedicated satellite cards for up and down links in native S, C, X, Ku, DBS and Ka bands.

• HIGH FREQUENCY WIDEBAND: Transmitters and receivers that cover frequencies from 1 GHz to 18 GHz, 22 GHz and 40 GHz.

• Q & V BAND: A new Q/V-Band transmitter and receiver card allowing signal transmission up to 60 GHz for the new series of satellite transponders.

Live Operational Requirements

Along with the widest range of frequency options in the industry, we also have a strong focus on true live operational requirements that include:

• CHASSIS OPTIONS: A range of different chassis options from a simple desktop unit, through to a 1RU and 3RU rack-mount unit to a fully temperature controlled outdoor unit.

• REDUNDANT POWER SUPPLIES: Our rackmount unit includes dual power supplies that mirror each other allowing a hot-swap facility if one fails meaning no down-time.

• NMS CONTROL: Full SNMP control allowing remote interrogation of the whole system along with APIs to integrate to most of the main high-level teleport management systems. RF AMPLIFIERS: The ability to have RF pre- and post-amplifiers up to 35 dB on the optical transmit and receive cards allowing a completely flat RF response across the link.

• FULL REDUNDANCY: We have a variety of inter-chassis RF splitters and RF switches to allow seamless redundancy in either auto-switch mode or under SNMP control.

• MULTIWAVELENGTH: Where connectivity between sites is limited, we have optical multiplexers and demultiplexers to allow multiple signals (wavelengths) to be carried over a single fiber.

• ETHERNET CONNECTIVITY: If a separate IP connection is not available between sites, we have an “in-band” Gb Ethernet card that allows you to control your remote site from your main station.

• OPTICAL AMPLIFIERS: High power lasers (typically 11dBo) allow us to achieve very long distances without the need for a mid-point cabinet. We also have chassis-based pre & post EDFA (up to 23 dBm amplifiers) that we can put either end of the link to enhance the link performance.

• DISPERSION COMPENSATION: We can provide dispersion compensation spools to stop the back reflection of light within the fiber due to the required high launch power of the transmitter when going long distances.

Fiber vs. Traditional Coax Cable The Benefits Are Well Known

Simplified installation of the cable run as fiber is 1/10th the weight and size of coaxial cable

• Long distances are possible (from 10 m to 100 km)

• Ability to keep the signal in the native satellite frequency reduces signal errors caused by up and down conversion

• Customers can run multiple signals over a single fiber with CWDM and DWDM technology

• Cleaner path with much simplified architecture and redundancy switching

• Fiber has great EMI immunity to avoid hum and distortion of the signal

• Fiber is much less expensive than coaxial cable over any reasonable distance

• Fiber optics provide a higher level of protection and security; lighting protection and virtually impossible to “tap”

Next Generation Plasma Thruster Now In Development By Magdrive

The rapid increase of smallsats being launched into Earth’s orbit is increasing at a phenomenal rate. From a total of 385 smallsats launched in 2019, the expectation now is that more than 6,000 will be launched during 2023, including SpaceX’s Starlink and Amazon’s Project Kuiper.

As satellites are evolving to be smaller, the development of agile propulsion technology to serve them effectively has not kept up. Magdrive has the answer to address the need for a breakthrough in satellite propulsion.

Magdrive is led by CEO Mark Stokes, a mechanical and deep learning engineer with a career in deep tech and aerospace, and CTO, Dr. Thomas Clayson, a plasma physicist and pulsed power electronic engineer.

Magdrive has just closed $2 million in seed funding from investors that include Founders Fund, who is a major investor in SpaceX. The company is currently working on an engineering model and currently speaking with prospective partners for OnOrbit Demonstrations.

The combination of high thrust and high specific impulse delivered by the Magdrive thruster are a generational leap ahead of any other propulsion systems. Other similar sized electric propulsion systems will typically produce less than 10mN of thrust, whereas Magdrive is looking to provide a colossal 100mN, providing small spacecraft with increased agility and control, sufficient for closeproximity operations and obstacle avoidance.

Left to right: Magdrive’s Mark Stokes, CEO, and

Dr. Thomas Clayson, CTO.

The Magdrive thruster consists of several magnetic coils, arranged to create a magnetic chamber. These coils confine and direct the hot plasma exhaust, provided by the pulsed plasma injectors. The unique element is the efficiency with which Magdrive manipulates the magnetic fields to direct the plasma to provide thrust. The high temperature of the plasma guarantees high efficiencies and specific impulses, while the high plasma density creates a high thrust.

Artistic rendition of a Magdrive prototype.

Magdrive are on an exciting trajectory since forming in September of 2019. The company was accepted into Entrepreneur’s First in April, accepted into the European Space Agency Incubator in June and secured the backing of Founders Fund.

Satellites are just the start for Magdrive, as Mark Stokes has much greater ambitions. He said, “Just as the jet engine transformed the aviation industry, the Magdrive will be the catalyst for a new space age. We want to open up the space industry to completely new types of missions that were not possible before without resorting to much larger, expensive and heavier chemical thrusters. Fast and affordable interplanetary space, operations in Very Low Earth orbit, and laying the foundation for orbital manufacturing and asteroid mining are all within reach. We plan to scale up our technology to power larger manned spacecraft once in orbit, to long distance destinations such as the Moon and Mars. Our system would present a much more affordable option than a chemical or nuclear solution, due to the huge reduction in fuel costs.”

Sateliot’s First Smallsat Is Ready to fly

Sateliot will launch a constellation of smallsats to democratize IoT with 5G coverage and has verified with Alén Space that the transmission equipment that will be on board its first smallsat is now ready to fly.

Once the design and manufacture of the flight model of the payload that will be on board 3B5GSAT — Sateliot’s first smallsat that will serve as a test bench — has been completed, both companies have worked on its integration into the satellite structure and its flight model, validating all its functionalities through strict tests and quality procedures.

Sateliot is relying on The Space Alliance formed by Thales Alenia Space (TAS) and Telespazio for the development of this constellation of smallsats to ensure the company’s IoT connectivity is compatible with the 5G standard.

These procedures, which have included tests of the complete system including the IoT terminals to be deployed on Earth, the satellite with the payload and the operating and data processing software, have concluded that everything is working optimally and that the satellite is now entering the final phase prior to its launch, which is scheduled for March 20 from the Baikonur space base in Kazakhstan.

With the launch of the first nanosatellite, Sateliot will enter a new technological phase, which will allow the company to perform field tests in real environments, providing very useful information for the evolution and design of its constellation of up to 100 nanosatellites that is scheduled to start and offer commercial service from 2022.

Alén Space, which signed an agreement with Sateliot as part of its R&D investment, is also already working on the new version of the payload to be carried on board the constellation’s next nanosatellites. The company will take advantage of the information collected by the first smallsat and will allow the implementation of a first version of the system capable of supporting a precommercial version of NBIoT.

This payload will be the hardware support on which the new standard defined by 3GPP for nonterrestrial networks will be implemented. In this context, Sateliot is working closely with both Alén Space and Gatehouse and I2CAT in the development and integration of the software needed to implement the new standard in the payload.

According to Jaume Sanpera, cofounder and CEO of Sateliot, “Despite the challenges and limitations posed by the pandemic in recent months, the development of our first nanosatellite brings us closer to our goal of having up to 100 nanosatellites in service by 2025”.

Sateliot is the first satellite telecommunications operator to provide global and continuous connectivity to all the elements that will make up the IoT universe under the 5G protocol.

Alén Space is a Spanish company specialized in consulting, design, manufacturing and operation of small satellites for all kinds of applications. Alén Space has a highly qualified team of engineers with more than 12 years of experience in the development of nanosatellite missions, with the necessary technological solutions and capacity to help those companies that want to develop business in space. Quality and technology have been the hallmark of the Alén Space team since 2008.