Trevor is a life-long entrepreneur and 2X founder with more than a decade of sales and business development experience in the technology and innovation sectors. His leadership and deep involvement in R&D at Atomic-6 have been instrumental in developing the company’s proprietary composite manufacturing process. He previously co-founded Sprout Lighting and served as Vice President of CRESA, Atlanta. A skilled strategist and connector, Trevor continues to push the boundaries of what’s possible in advanced materials and aerospace composites.

What is the purpose of Atomic-6?

Trevor Smith

Trevor Smith

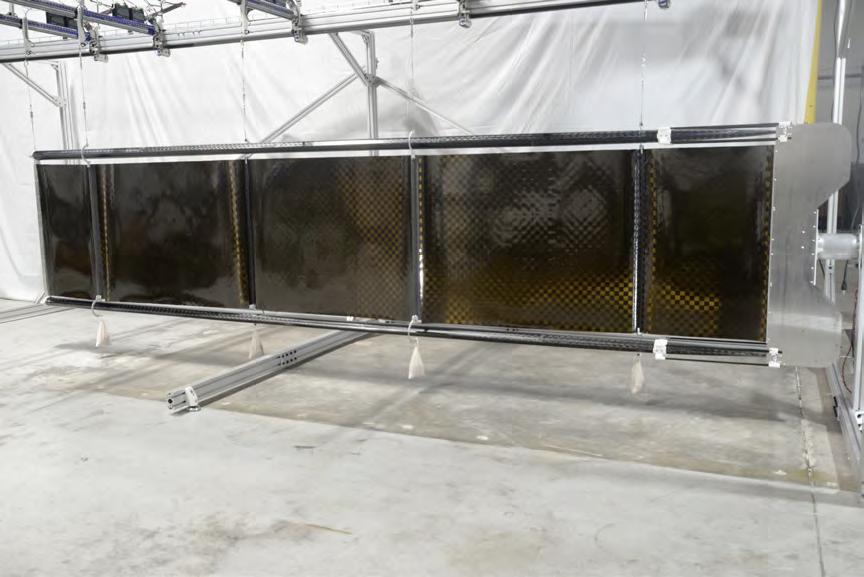

We exist to put gigawatts and enable petaflops in orbit, reliably, affordably, and at scale. We manage that through the Light Wing™ array (photo below), our all-composite, high specific-power, re-deployable, mass-producible, solar array that is built for modern space operations.

On too many missions, the solar array is the most expensive (~30% of BOM), longest-lead (often 12 to 18 months), and most failure-prone subsystem, historically implicated in a large share of

on-orbit failures. Teams are paying a fortune for the very part that arrives late and jeopardizes mission success.

Light Wing™ array flips that script. Standard unit configurations target manufacturing at roughly six weeks from order to shipment, a dramatic improvement over traditional timelines. We’ve proven resilience through more than 50, full deploy-and-retract cycles on hardware, meaning operators can roll the system back in, troubleshoot and redeploy without ending the mission.

Performance is world-class, with a power-to-mass ratio approaching 200 watts per kilogram on our 2-kilowatt-class architectures. As the structures are stiff and tensioned, they reduce jitter for sharper imaging and more stable communications, while true redeployability unlocks Rendezvous and Proximity Operations (RPO) windows, threat avoidance, stealthier profiles, and rapid reconfiguration on-orbit.

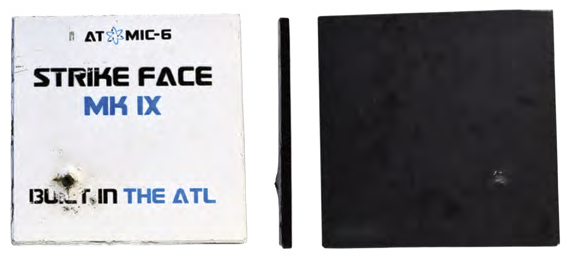

The second half of survivability is protection, which is why we also build Space Armor™ tiles (image, upper left, next column), a Micrometeoroid Orbital Debris (MMOD) shield that’s lighter, thinner, and, in high-speed testing, did not shed secondary fragmentation or spalling on impact. If we’re serious about a sustainable space economy, we have to stop turning one impact into a cloud of hazards.

Thankfully, Space Armor™ tiles can take care of that... Light Wing™ arrays are designed for power and Space Armor™ tiles for protection, “Made in America,” and built to ship in weeks... not years.

It’s the pick-and-shovel play for space infrastructure and is really a game changer for operators everywhere at this critical historic moment.

How certain are you that space is becoming a hostile environment?

Trevor Smith

Certain enough to build a company around it—the trend lines are undeniable: RPOs aren’t always friendly, routine jamming and spoofing from the ground occurs often, and debris events ratchet up the risk for all.

Direct-ascent ASAT (DA-ASAT) tests have already shown what a single kinetic event can do to Low Earth Orbit (LEO). Add in near-daily cyber probing of ground segments, and you’ve got a domain that’s contested, congested, and competitive.

Space used to be treated like a sanctuary. It isn’t anymore. That reality breaks old engineering assumptions, from power budgets and pointing stability to thermal margins and maneuver duty cycles.

If you design your spacecraft as if the environment is benign, you’re planning for a world that no longer exists. That’s why we anchor on power and protection as our firm’s first principles.

What are the stakes for getting the space race right?

Trevor Smith

They’re existential for American security and prosperity. Deputy Secretary of Defense Kathleen Hicks put it plainly and best in 2024 when she said, “Our way of life and our way of war depend on space power. GPS doesn’t just guide munitions; its timing disciplines these financial system. Weather, agriculture, logistics, telecom, ISR, all are space-enabled.”

For deterrence to hold, our space layer has to work on the worst day, not just the best. My personal bar: I won’t be comfortable until our critical satellites can withstand an all-out surprise attack, ride through a system-level cyber breach, and survive a Carrington-level solar storm, all on the same day, and still fight through.

We’re not there yet. Getting there requires orders of magnitude more power (to sense, compute, and maneuver harder) and protection (to keep operating when the environment turns ugly).

Flip to the upside: In 50 years, industry will be using microgravity, extreme hot/cold environments, and abundant sunlight to run cleaner processes and manufacture what’s impossible to accomplish on Earth, tapping the 99.9999% of solar-system mass that isn’t here as of this article. I’ve said it before: the biggest numbers are out in space.

However, you don’t reach that future without resilient infrastructure... now. As we like to remind folk: Only you can prevent orbital debris! That’s why Space Armor™ tiles matter to sustainability as much as survivability.

Why manufacture solar-arrays.. and why now?

Trevor Smith

Why? Because capacity is the constraint. Our read: today’s array manufacturing serves well under 90% the demand expected during the next five years. Everyone sees it program-side that cells are available, but the flight-ready structures and mechanisms are the long pole in the tent inflating costs and pushing timelines. There’s no true “gigafactory” to absorb the surge.

The Light Wing™ array is engineered for rate. Its all-composite structure and memory hinge eliminate heavy metal spring packs and their failure modes. Instead of bulky sandwich panels, we use ultra-thin tensioned back sheets—measured in thousandths of an inch—that pull into stiffness on deployment.

The entire manufacturing process is “Starlink-inspired,” with digital flow from quote to QA for full traceability and process control. It’s designed to keep power literally on the shelf.

Under the hood, the metrics are just as compelling. We’ve demonstrated a ~1 kW article in our warehouse that weighs only ~8.5 kilograms —including the deployer—and we’re approaching ~200 W/kg in optimized 2 kW-class configurations. The system has been cycled more than 50 times, with a gravity offloader and continues to perform. For standard configurations, lead times target about six weeks. Its first flight is confirmed to occur in 2027, but there are also some options for flying in 2026. Our composite hinge naturally wants to return to the deployed state, making deployment clean, repeatable as well as reversible. We lead in power-to-mass, with stiff structures that reduce jitter for higher-fidelity sensing and comms. Our team carries factory scars from shipping real hardware—from Starlink production to hypersonics—which means we know what it takes to deliver beyond CAD renderings.

Strategically, you don’t have to bet on a single constellation when you can bet on success with

the infrastructure that every constellation needs.

What does redeployability unlock that fixed arrays can’t?

Trevor Smith

It turns power from a static constraint into a dynamic capability. During RPO and docking, arrays can retract to reduce collision risk, visual signature, and low-altitude drag, then re-extend once the satellite is mated or station-kept.

In a threat scenario—say, an ASAT launch warning with only minutes of notice—the system can stow quickly, execute a hard burn and then redeploy to recharge and resume operations. The architecture’s tensioned stiffness reduces jitter, improving both imagery and high-gain link stability.

When paired with deployable radiators—our Space Mast™ concept—the system can export heat to support edge compute and high-power payloads, even enabling on-orbit data centers.

In servicing scenarios, the ability to pull arrays fully out of the way makes capture and repair windows wider, and insurers far more comfortable. Redeployability lets operators experiment on-orbit: adjust area, attitude, and tempo to maximize mission revenue, not just survival.

What other tech disruptions are Atomic-6 riding, solving for, or responding to?

Trevor Smith

There are three big ones...

1) Redeployability as a mission primitive. Think of Light Wing™ array as surface-area manipulation. Satellites can move, see, and talk, all three depend on how you present area to the environment. We’re thinking about using the deployable structures proven with Light Wing™ arrays to do radiator heat rejection. With that Light Wing™ architecture, you dial area up for power and thermal rejection; dial it down to cut drag and signature for fast slews, docking windows, or stealthier profiles; then re-deploy to resume high-power ops. That flexibility de-risks RPO, improves imaging (lower jitter, higher stiffness, faster settling times), and makes in-space servicing more forgiving, and more insurable.

2) Autonomy everywhere. Ground teams will eventually be able to manage 10× more spacecraft at the same headcount. On-orbit autonomy will optimize profiles and squeeze ~20% more profitable life out of hardware. Our job is to supply the watts and thermal headroom to make autonomy usable: edge compute, AI inference, sensor fusion, high-rate cross-links, none of that runs on good intentions. It runs on power.

3) The industrial-base reset. Launch is cheaper and heavy-lift is coming online. Constellation demand is surging. But solar arrays are the bottleneck, not the cells, the structures and mechanisms. There’s no “gigafactory” for arrays today. Customers quote 18-month waits for a component that kills too many missions when it fails. The answer isn’t a clever one-off; it’s a factory that turns reliable power plants out at rate. “Formula-1 race car meets LEGO-brick manufacturing” is our mantra.

How is my background unique, and how have I turned that into an advantage?

Trevor Smith

I didn’t come up the traditional astro/DoW ladder. I grew up on a small farm in northwest Mississippi, fell in love with things that go fast (motorcycles at six, yes, without a helmet; sorry, Dad, I blame Mom!), and started my career in commercial real estate after a degree in Real Estate Finance. I’m gainfully unemployable in the best sense: I like building, selling, and getting hands-on when it counts.

The pivot into composites happened the way the best founder stories do, over cigars and tequila, and it crystallized the question that still drives Atomic-6: How do we deliver aerospace-grade performance at production rates that look more like automotive?

I bootstrapped Atomic-6 with a second startup, a lighting business, to fund early R&D. My wife was my first VC, insofar as she paid the bills while I ran around with composites in my backpack. I learned to program an autoclave via YouTube and, in one hair-raising episode, learned what a pressure-relief valve does the hard way. (We lived to tell it.)

A NASA model once predicted Space Armor™ tiles wouldn’t work. We ran the shot anyway, 3 mm aluminum at roughly Mach 21, and it worked first time, with no secondary debris in the high-speed footage.

Commander Chris Hadfield signed that first panel; he also told me the ISS sounds like rain on a tin roof from micro-impacts. That stuck with me, and highlighted the importance of not taking status-quo protection up in space for granted.

I’ve paired my storytelling/sales DNA with world-class technical leadership. Our COO came from SpaceX, interviewed by Elon Musk and Tom Mueller, designed Starlink propulsion, co-designed half the factory, and led the team that put the first 1,400 satellites up. More than a résumé, Christian has production muscle memory and he is our systems and propulsion ace, working shoulder-to-shoulder with customers and keeps us brutally honest on architecture.

Culturally, we’re hands dirty, egos low, speed high. We host middle- and high-schoolers on Saturdays to lay up carbon fiber because this field needs builders who believe they can do it.

I learned a ton as a founder with Starburst Aerospace and Creative Destruction Lab, and now as a mentor grilling the next cohort. Great advisors and VCs help, too. (Shoutout to Thiago Olson at Eve Atlas for literally hopping in the truck to go to Home Depot with us mid-build.) Also: mechanics from auto shops make fantastic composite techs. Love you guys!

What do you want policymakers, investors, and prime contractors to understand right now?

Trevor Smith

First: No one wants less power. A VC once told me, “No one uses extra capability to save money; they use it to make more money.”

In space, watts are options, compute, sensing, mobility, resilience, and at the end of the day, profit. The missions that matter scale with power.

Second: Solar arrays, not cells, are the chokepoint. If your Gantt chart treats arrays like a commodity, it’s lying to you. Fix this, and you unlock timelines and risk across the portfolio. The U.S. needs product on the shelf and ready to ship.

Third: Set a survivability baseline. Design for cyber, EM, kinetic, debris, and solar weather. Power and protection are the cheapest insurance you can buy, pre-launch.

Fourth: Space isn’t going anywhere. Investment is durable, heavy launch is arriving, and national-security customers are crystal clear about space as the linchpin of joint operations and freedom of navigation. Align budgets and acquisition with that reality and the private sector will meet you with capacity.

Near-term from Atomic-6: Light Wing™ array product line locking, pre-engineered menus expanding, and a production line maturing into a true solar-array factory. On the protection side, Space Armor™ tiles are moving through flight-qualification with RF-permeable variants for comms. We’re pairing Light Wing with deployable radiators and Space Mast modules for high-power payloads and on-orbit compute. Our goal is simple: power on the shelf; armor on orbit.

Why are power and protection the center of gravity for spacecraft design now?

Trevor Smith

Because a hostile domain shreds legacy assumptions. For decades, engineers designed spacecraft on the premise that once you were in orbit, the environment was relatively stable.

That’s no longer true. Unexpected slews and unplanned maneuvers eat into pointing budgets and fuel margins. Counterspace threats, from jamming and spoofing to rendezvous-and-proximity operations, force vehicles to maneuver in ways they weren’t budgeted for.

Autonomy and edge AI, once aspirational, are now table stakes, but they consume far more watts than the old spreadsheets predicted. Thermal is no longer a line item you worry about at the end, it’s becoming the hard limiter on how much computation, sensing, and communications a spacecraft can sustain. That’s why power and protection aren’t secondary considerations; they’re the center of gravity.

The Light Wing™ array gives spacecraft the headroom via power, stiffness, and redeployability to absorb those unexpected hits without punting the mission. With it, operators can surge power for high-bandwidth comms, precision sensing, or edge compute when the mission demands it, then stow and maneuver with agility when the threat picture changes.

On the protection side, our Space Armor™ composite tiles keep satellites alive when the environment turns against them. They absorb and dissipate kinetic energy without producing dangerous secondary debris clouds, meaning one strike doesn’t multiply into hundreds of new hazards. Because the armor is formidable and RF-permeable, it can protect apertures, comms, or even crew without blocking the very functions you need to keep the mission going.

Together, Light Wing™ and Space Armor™ form the foundation for resilient spacecraft in the decade ahead: platforms that don’t just survive, but continue fighting through surprises, whether it’s an adversary’s action, a cyber breach, or a natural event like a solar storm. In an era where the difference between mission success and failure can hinge on a handful of minutes, power and protection are no longer luxuries. They are the baseline. Remember, what truly differentiates Atomic-6 is simplicity, performance, and credibility.

Final thought: Why me? Why this team? Why now?

Trevor Smith

My résumé doesn’t say “destined to run a space company.” It says obsessed with speed, willing to learn, comfortable selling the vision, and stubborn about shipping. That mix, paired with a technical team that’s built some of the most consequential space hardware of the last decade, is exactly what this moment needs. We’re not here to craft a few beautiful, artisanal arrays a year. We’re here to build the factory that reliably powers deterrence, a new industrial economy, and yes, your mission!

We’ve found our Big Juicy Target in space power through redeployable arrays. The key to space is power. The key to power is Light Wing™ array. Space requires power and protection. Atomic-6 supplies both. Let’s go.

atomic-6.com