Dr. Lucinda King, Mission Concepts Engineer at In-Space Missions (part of BAE Systems)

Between 2030 and 2040, it’s expected that thousands of satellites will be launched into low Earth orbit. Many of these satellites will perform vital services that underpin society—from ensuring connectivity and delivering navigation services such as GPS, to supporting our militaries and helping scientists monitor the environment. But what about in-orbit satellites that are no longer functional?

The reality is that space is full of parts from obsolete satellites and rockets, which hurtle around at a rapid pace and threaten to damage operational spacecraft. While satellite launch rates have increased, efforts to limit space debris have not kept up. In fact, the European Space Agency (ESA)’s Annual Space Environment Report found that if this trend continues, crucial orbital regions could become unusable.

If future generations are to continue to benefit from all the opportunities space offers, we need to urgently find ways to lay the foundation for a more sustainable sector now. This is why ESA has pledged to implement a circular economy in space by 2050.

If future generations are to continue to benefit from all the opportunities space offers, we need to urgently find ways to lay the foundation for a more sustainable sector now. This is why ESA has pledged to implement a circular economy in space by 2050.

Quick fixes are not an option; solutions need to ensure long term sustainability, which means looking at ways to build and maintain satellites in space. This involves a segment of the space industry known as In-Orbit Servicing, Assembly and Manufacturing (ISAM) which also includes solutions for in-orbit recycling.

We must also recognizse that circular space economy cannot be achieved by any one organisation alone. It requires collaborating with purpose across the space community (and beyond) to develop innovative technologies that have real longevity. What does this look like in practice? What solutions are currently being explored? And how are isat BAE Systems Digital Intelligence playing its part? On-orbit servicing, assembly and manufacturing

A key part of implementing a circular space economy involves finding ways to safely de-orbit non-functional satellites, as well as maximising the utility and functionality of satellites while they are in-orbit. This can be enabled by ISAM – a fast-growing area which, according to research, presents an estimated £11 billion opportunity to the global space industry. Plenty of important ISAM work is already taking place.

For example, Astroscale— a leader in satellite servicing and long-term orbital sustainability—recently completed a project called ELSA-d. This was a mission to remove debris from Low Earth Orbit (LEO) in a safe and controlled way, using Astroscale’s ‘Chaser’ servicer satellite and a ‘Target’ satellite which replicated space debris. Additional examples include developing other solutions for active debris removal, as well as extending the life of satellites through refuelling and re-orbiting.

However, space sustainability is not just about safely removing or refuelling and then re-orbiting spacecraft. It’s also about reducing the number we launch in the first place. Another emerging and novel example of ISAM is refurbishing and upgrading in-orbit spacecraft robotically, rather than de-orbiting and replacing non-functional satellites. The idea is to enhance the utility and functionality of satellites to ensure they last longer and work better when they are in-orbit – and this is where we come in. Designing a service to upgrade satellites in-orbit

Designing the client satellite in this way means that if one of its parts becomes damaged, or is no longer operating efficiently, the servicer satellite can replace the part in-orbit. This is a game-changing way to think about space technology. It saves costs and resources associated with de-orbiting satellites, reduces the number of satellite launches required to replace satellites that are no longer functional and, most importantly, lays the foundation for a more sustainable, circular space economy.

Designing the client satellite in this way means that if one of its parts becomes damaged, or is no longer operating efficiently, the servicer satellite can replace the part in-orbit. This is a game-changing way to think about space technology. It saves costs and resources associated with de-orbiting satellites, reduces the number of satellite launches required to replace satellites that are no longer functional and, most importantly, lays the foundation for a more sustainable, circular space economy.

When ESA announced its commitment to create a circular space economy by 2050, it called for creative system concept ideas that could provide on-orbit refurbishment, manufacturing and recycling. Responding to the call, we worked in a consortium led by Astroscale UK to develop a concept for an In-orbit Refurbishment and Upgrading Service (IRUS).

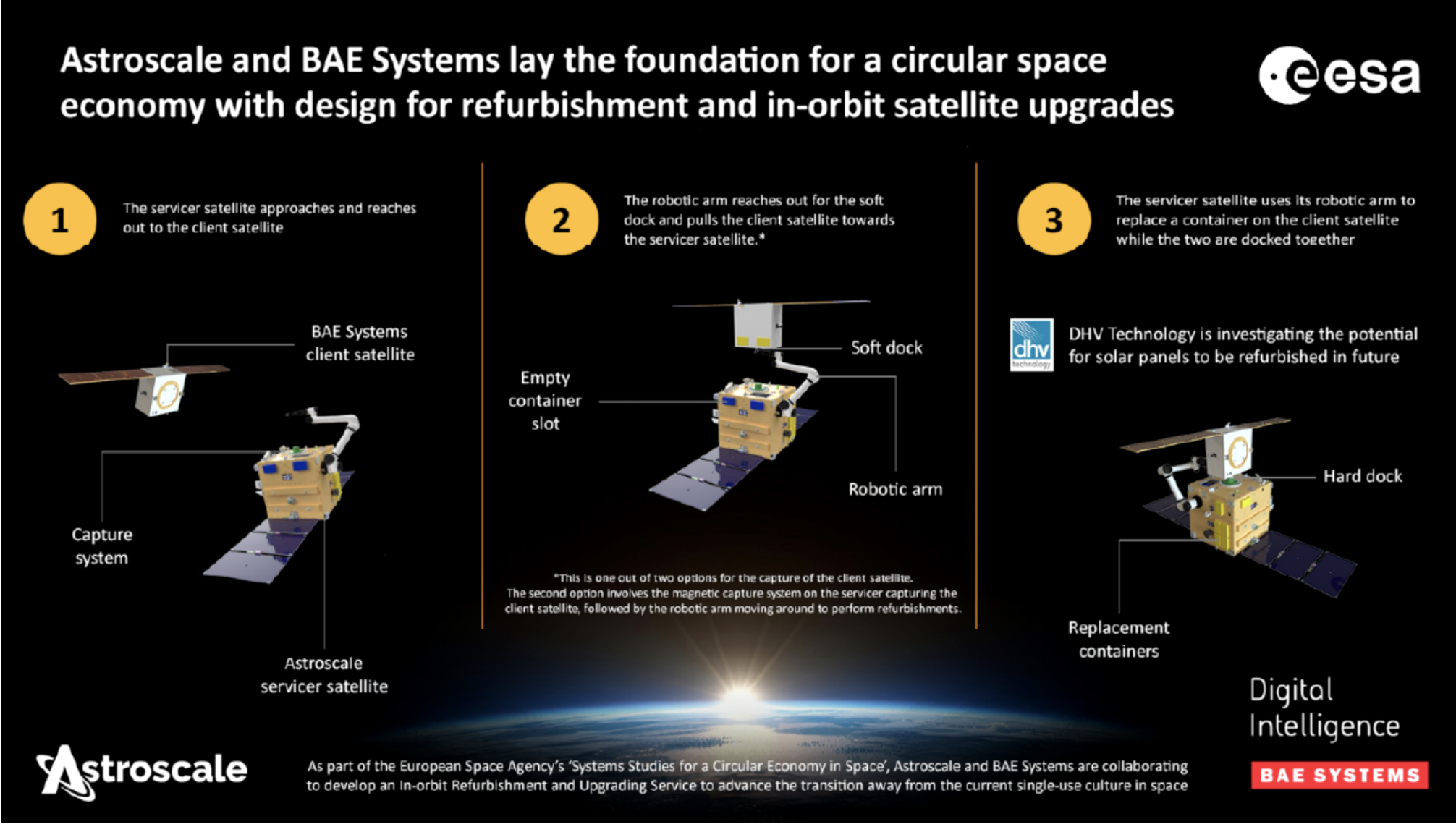

As part of the IRUS project, we designed a BAE Systems client satellite which is capable of being upgraded and refurbished by Astroscale’s servicer technology in space. We explored modular, serviceable ways to build our client satellite, so that Astroscale’s servicer satellite would be able to robotically upgrade specific modules.

DHV Technology, an international manufacturer of bespoke solar array systems and spacecraft power subsystems, was also part of the project. Its team researched wider impacts and potential applications of refurbishment and upgrading on solar cell technologies more broadly, helping to expand the scope of the study.

What could IRUS look like? Click to enlarge.

Click to enlarge.

In March, ESA reviewed our design alongside ideas from other consortiums. Excitingly, we were the winning consortium and were awarded a session at ESA’s state-of-the-art Concurrent Design Facility (CDF)—a space that facilitates intense co-operative design work. This enabled our team to collaborate with experts from ESA who specialise in robotics, interconnectors, attitude and orbit control, thermal engineering and cost. It was a really productive session, during which we refined the design of the client spacecraft and progressed the overall mission operational concept.

Over the coming months, we will work with ESA experts to further develop the mission concept and gather support for it at the next ESA ministerial in November 2025. Only the beginning...

ISAM is a rapidly growing part of the space market for a reason: the sector knows how crucial it is to the future success of the space industry. The technologies developed for in-orbit repair, upgrade, recycling and assembly may well be those that support humanity’s ambition for a long-term presence on the lunar surface and beyond. And alongside supporting the sustainable use of space, they can also enable flexible and responsive space solutions to a range of challenges.

Dr. Lucinda King Importantly, the development of ISAM technology needs to happen within the framework of evolving regulation and legislation, which calls for clear dialogue between all industry stakeholders, as well as the right expertise within government to shape legislation. The IRUS project, for example, will help to highlight the challenges of in-orbit servicing regulation going forward.

Concepts like IRUS are only the beginning. By working together and applying cutting edge, interoperable technology, we can build solutions that create long-term, sustainable change.