GHGSat: Satellites reveal methane as an unintended consequence of palm oil production and points toward solutions

Palm oil, the world’s most widely consumed vegetable oil, is an inescapable component of most manufactured consumer products, present in roughly 50% of supermarket packaged products ranging from pizza to toothpaste, or products like animal feed and biofuels.

Grown primarily near the equator, palm oil production is incredibly efficient, with the highest yield per hectare among vegetable oils, but still has traditionally been known for its deforestation impacts, as rainforest in tropical areas has been cleared to make way for plantations.

Grown primarily near the equator, palm oil production is incredibly efficient, with the highest yield per hectare among vegetable oils, but still has traditionally been known for its deforestation impacts, as rainforest in tropical areas has been cleared to make way for plantations.

While the deforestation impacts are widely known, satellites are now also beginning to uncover a previously unseen impact of palm oil production: methane emissions.

Methane from palm oil mills is not unexpected, as it stems from the industry’s standard production processes and byproducts. Palm oil production produces a large amount of wastewater, known as POME (palm oil mill effluent), which is typically stored in open ponds. As the organic waste in the ponds, such as pulp and shells from the palm fruits, decomposes, it produces methane in a process much like decomposing trash in a landfill. The pond system was designed to curb local water contamination from releasing POME into the riverways and channels, but had an unintended impact. Now, however, for the first time it can be accurately quantified by satellites.

Now, the ability of satellites to quantify the methane from palm oil mills paves the way for potential better accounting of the industry’s total environmental impacts and effective, profitable mitigation of the emissions.

Following the publication of a scientific study in Environmental Research Letters, which confirmed the accuracy of GHGSat’s high-resolution satellites in measuring methane from palm oil mills, GHGSat’s constellation has increasingly homed in on palm oil ponds in tropical regions around the world, including South America, Asia, and Africa. As of late April 2025, GHGSat’s fleet of satellites has identified more than 50 methane emissions from 12 different countries.

Following the publication of a scientific study in Environmental Research Letters, which confirmed the accuracy of GHGSat’s high-resolution satellites in measuring methane from palm oil mills, GHGSat’s constellation has increasingly homed in on palm oil ponds in tropical regions around the world, including South America, Asia, and Africa. As of late April 2025, GHGSat’s fleet of satellites has identified more than 50 methane emissions from 12 different countries.

Landfill operators and municipalities with similar methane challenges have seized on the potential of waste diversion, recycling, or and gas capture systems to limit methane emissions or even transform them into a source of additional profit—converting it to natural gas to sell back to local power grids or power on-site operations. Similar approaches and technologies exist for palm oil mill operators.

The Roundtable on Sustainable Palm Oil (RSPO) was formed in 2004, and sets sustainability standards for the palm oil sector, certifying growers that meet those standards. Alongside other initiatives related to deforestation and workers’ rights, RSPO has developed a PalmGHG calculator to enable palm oil growers to estimate their net greenhouse gas emissions and implement more sustainable practices.

Palm oil is a $48.1 billion industry, concentrated in countries near the equator, with Indonesia and Malaysia estimated to produce roughly 90% of the global supply. The Roundtable for Sustainable Palm Oil estimates that the industry provides a living for some seven million smallholder farmers globally, including direct jobs for four million people in Indonesia and nearly a million in Malaysia. Many of the economic benefits of palm oil are focused in remote, rural areas where work can be hard to find.

“This is the power of high-resolution satellite technology: it illuminates a previously opaque challenge, and delivers the insights required to map out a solution,” said Stephane Germain, CEO of GHGSat. “Precise data is the first step toward action, and satellite technologies are a part of the puzzle.”

www.ghgsat.com

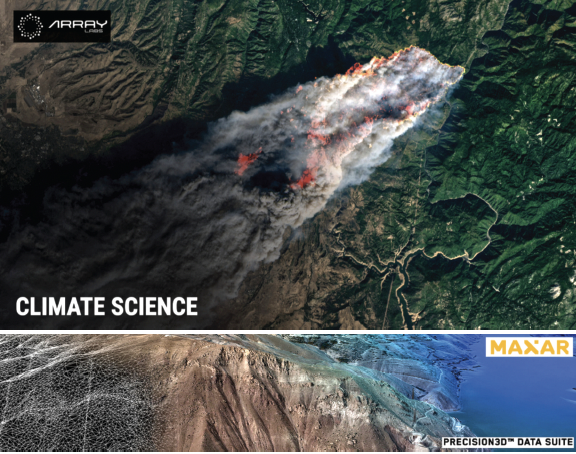

Maxar partners with Array Labs to fuel the company’s 3D operational terrain

Array Labs’ upcoming constellation will fuel rapid updates to Maxar’s global 3D terrain, providing unparalleled insights for warfighters, analysts and commercial operators.

Both firms recently reached an agreement wherein Maxar will be provided with dedicated capacity from Array Labs’ 3D radar imaging constellation, which is set to launch in late 2026.

Both firms recently reached an agreement wherein Maxar will be provided with dedicated capacity from Array Labs’ 3D radar imaging constellation, which is set to launch in late 2026.

This partnership will combine very high-resolution 3D terrain generated from electro-optical imagery with 3D terrain generated from radar imagery to expand Maxar’s ability to rapidly update its global 3D global data in real-time. Under the agreement, the two companies will extend the current technical validation activities and work closely to integrate Array Labs data into the Maxar 3D product line.

Rapidly updated 3D global terrain data provides defense, intelligence and commercial customers with unparalleled insights into their true operating environment and enable opportunities to further enhance the capabilities of next-gen tactical mission-focused products like Raptor, which provides GPS resilience for autonomous drone systems.

Maxar’s 3D global terrain data already consists of 100 million-plus sq km around the world, delivered with 3-meter SE90 accuracy. This data is regularly updated to provide a reliable view of the operational terrain.

Once Array Labs’ constellation is operational, it will become the latest addition to Maxar’s virtual constellation, which brings together complementary remote sensing capabilities to enable comprehensive, real-time geospatial insights and intelligence.

ION-X achieves first firing in space of a European Ionic Liquid Propulsion System

ION-X has successfully performed the first-ever in-orbit firing of a European-developed ionic liquid electrospray thruster.

This milestone marks only the second global demonstration of this advanced propulsion technology in space, nearly a decade after the inaugural mission by BUSEK for the LISA-PATHFINDER mission in 2015.

This milestone marks only the second global demonstration of this advanced propulsion technology in space, nearly a decade after the inaugural mission by BUSEK for the LISA-PATHFINDER mission in 2015.

On May 6th, 2025, onboard a spacecraft built by Danish satellite manufacturer Space Inventor and launched on SpaceX’s Transporter-12 mission in January of 2025, ION-X’s thruster emitted its first ion beam in Low Earth Orbit (LEO).

Triggered by its onboard computer and powered by ION-X’s proprietary Power Processing Unit (PPU), the system successfully generated thrust estimated at 20 μN, with an ion beam of 200μA at 5kV. Tests in orbit are still on-going, and this is already a significant achievement for the company.

The first ionic liquid electric propulsion system was developed by BUSEK under a NASA contract and launched in 2015 for the LISA PATHFINDER mission.

The first ionic liquid electric propulsion system was developed by BUSEK under a NASA contract and launched in 2015 for the LISA PATHFINDER mission.

Ten years later, ION-X demonstration is only the second occurrence worldwide of an ionic liquid electrospray firing in space—and the 1st from a European company.

Market ION-X’s compact and scalable thruster is tailored to meet the growing demand for high-precision, low-power propulsion systems. It addresses critical use cases such as constellation deployment, collision avoidance, and station-keeping for small satellites. Its electrospray design enables extreme miniaturization, low plume contamination, and high pointing accuracy, key performance drivers for satellite manufacturers and mission integrators.

The first flight model was integrated on the Space Inventor’s EDISON spacecraft in May 2024, just three years after ION-X’s incorporation and with a total budget under €4 million, a remarkable programmatic, financial and technical achievement in the field of space propulsion.

As the EDISION mission is expected to terminate this summer, ION-X is already gearing up toward its next space missions. The second flight of the company’s thruster shall be publicly announced in the coming weeks, for a launch expected by mid-2026.

This will give the opportunity to the company’s team of engineers and scientists to fly an even more sophisticated version of its propulsion system, with the aim to demonstrate increasing performances and accelerate its commercial and industrial development.

“We worked really hard over the past three years to achieve these first results. I am immensely proud and grateful to the ION-X team. We could not have done it without their dedication and professionalism. There is still a lot of work to increase the performances and the reliability of our thruster but this is a clear sign that we are going in the right direction,” said Thomas Hiriart, ION-X CEO. “This achievement is the culmination of three years of intense R&D made at C2N, the nanoscience laboratory of CNRS located in Palaiseau, south of Paris. It marks a major step toward the deployment of European-made electrospray propulsion technologies for the next-generation of space missions.”

About ION-X

ION-X is a French startup founded in May 2021 by Jacques Giérak, a world-renowned expert in ion sources for nanoelectronics and Research Engineer at C2N (Nanoscience and Nanotechnology Laboratory of CNRS, Palaiseau, France). Mr. Giérak was awarded the CNRS Innovation Medal in 2023. The company was co-founded with Yves Matton, Partner at the venture builder Technofounders. ION-X develops a new electric propulsion system based on the ejection of ultra-fine, fully ionized particles, primarily designed for small satellites. This system is based on patented technology jointly developed by CNRS and CNES. ION-X is backed by Expansion, Technofounders, the European Innovation Council, Innovacom, the Ile-de-France Région and BPI France.