In today’s strategic information environment, the ability to rapidly respond to ever-changing technology needs is an essential asset for any organization that provides critical services to its customers.

Perhaps nowhere else is this more prevalent than in the high-demand field of space operations. With the recent revolution in launch and exploration through private and commercial options, there is an unprecedented opportunity for increased space access.

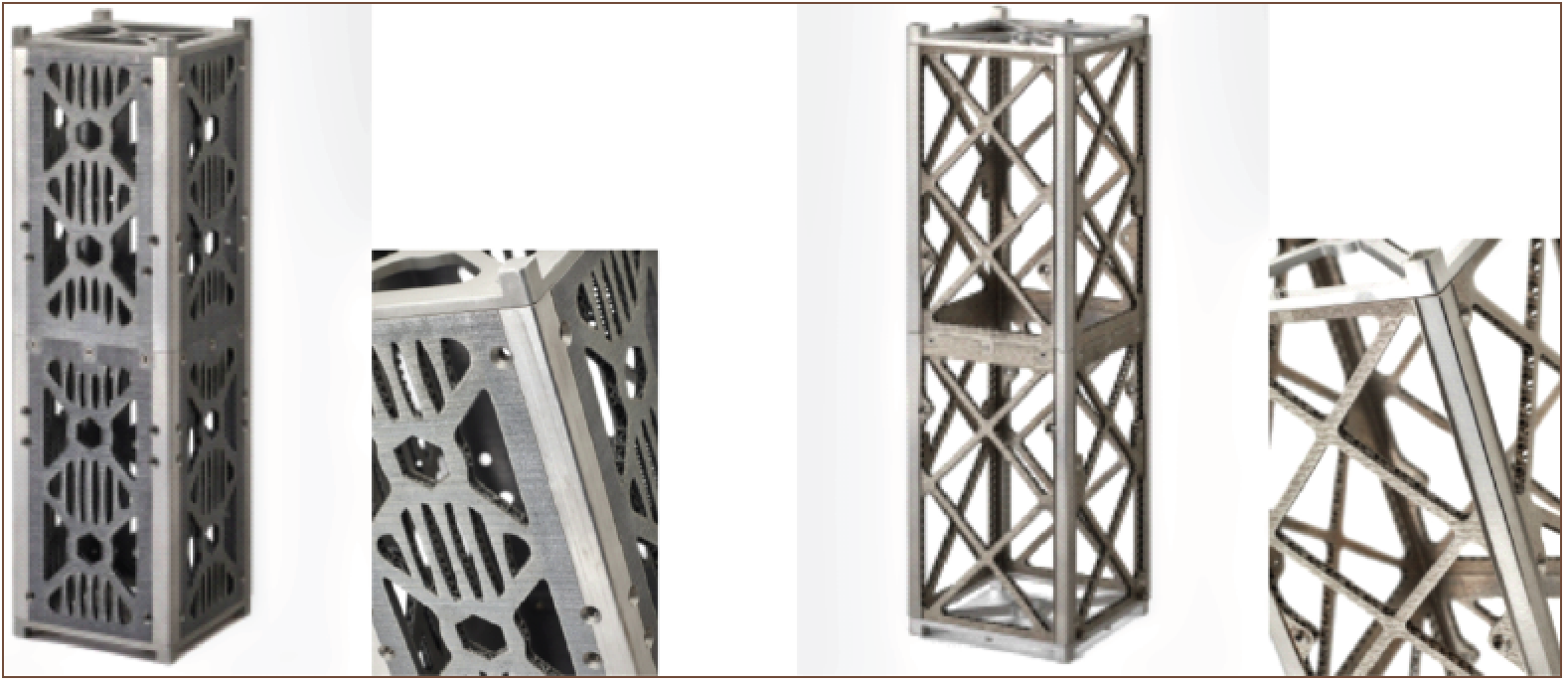

Image 1 a,b,c,d. (Left-to-right): Previous aluminum alloy cubesat bus (chassis) design, and close-up detail, contrasted with Inconel cubesat bus redesign and close-up detail. The direct-to-manufacturing capability in nTop Platform software enabled the creation of an additively manufactured alternative structure that was half the weight of the aluminum alloy design, with a 20 percent increase in stiffness.

Image 1 a,b,c,d. (Left-to-right): Previous aluminum alloy cubesat bus (chassis) design, and close-up detail, contrasted with Inconel cubesat bus redesign and close-up detail. The direct-to-manufacturing capability in nTop Platform software enabled the creation of an additively manufactured alternative structure that was half the weight of the aluminum alloy design, with a 20 percent increase in stiffness.

One avenue for access that has garnered significant attention of late is “ridesharing,” a popular methodology for launching numerous satellite payloads together on a structural “bus” into Low Earth Orbit (LEO). Such shared payloads can host a variety of smallsats, often grouped in multiple 10 cm cubic units, with the 3Unit cubesat being the most popular. Some 1,000 cubesSats have been launched as of January 2019, most of them successfully. Functions of the satellites include Earth Observations (EO), amateur radio, scientific experiments, and more.

The use of cubesats is enabling a shift in focus from large single satellites to smaller distributed networks of multiple ones. As an aggregate, these can provide capabilities similar to larger satellites, but through a much lower-cost and lower-risk system.

With increased use of these smallsats and the need for design and performance optimization of the structural bus that supports them, some researchers are taking a closer look at additive manufacturing (AM, aka — 3D printing). By leveraging a computational, Architected Materials approach to designing the bus, this primary physical structure upon which the satellite subsystems are mounted can be made lighter, stronger and quickly re-sizeable to accommodate specific satellite loads.

The structural bus forms the backbone of the satellite and provides the basic infrastructure necessary for the satellite to function. The physical modularity of the bus and payload system allows for a smallsat to be easily configured. However, there is a significant process expense when satellite integrators are forced to manage and control the use of high-failure fasteners and complex assembly processes to prevent these fasteners from loosening during operation.

Software for AM Enables Creation of Architected Materials

Researchers at the U.S. Air Force Institute of Technology (AFIT) have leveraged advanced computational engineering and design software capabilities to increase the stiffness of a structural bus while reducing weight, part count, and delivery lead time. Space satellites require materials with superior stiffness to weight ratios to provide structural integrity while minimizing mass.

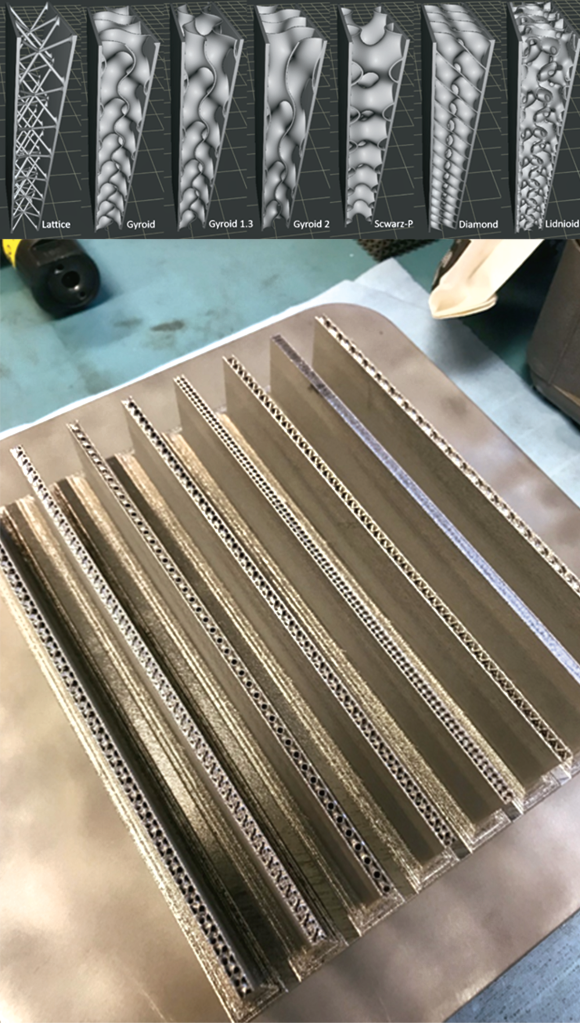

Image 2. (Top) internal lattice and gyroid design

options generated in nTopology software and

(bottom) 3D-printed samples of options printed

on a Concept Laser M2 Cusing machine.

Several critical technologies were used to produce a cubesat that could be rapidly built with AM equipment driven by nTop Platform software and its advanced-geometry engine. The software delivers an algorithm-based modeling environment that enables engineers to create lightweight and optimized parts with functional requirements built directly into the model.

Critical to the reduction in weight for this cubesat bus was the use of a high stiffness thin-walled structure capable of meeting the launch and payload delivery requirements of a launch-provider customer.

Designing a high-stiffness structural bus was made possible through the reduction in its volume via a three-dimensional honeycomb structure. This structure was composed of unit cells of a thin-wall, triply periodic minimal surface (TPMS) known as a gyroid.

Experimental tests were performed to identify the unit cell type, period, and size that would deliver the highest stiffness to weight unit cell for a 3U cubesat structural bus.

Several critical technologies were used to produce a cubesat that could be rapidly built with AM equipment driven by nTop Platform software and its advanced-geometry engine. The software delivers an algorithm-based modeling environment that enables engineers to create lightweight and optimized parts with functional requirements built directly into the model.

Critical to the reduction in weight for this cubesat bus was the use of a high stiffness thin-walled structure capable of meeting the launch and payload delivery requirements of a launch-provider customer.

Designing a high-stiffness structural bus was made possible through the reduction in its volume via a three-dimensional honeycomb structure. This structure was composed of unit cells of a thin-wall, triply periodic minimal surface (TPMS) known as a gyroid.

Experimental tests were performed to identify the unit cell type, period, and size that would deliver the highest stiffness to weight unit cell for a 3U cubesat structural bus.

The modeling technology in the software made it possible to perform a design of experiments (DOE) that enabled the identification of the highest stiffness-to-weight structure extremely quickly. (Please see Image 2.)

Identifying the Optimal Material, Designing it for AM

The researchers explored the potential of various metamaterials for the bus structure via computational evaluation. Using the software to query the performance of thin-wall periodic implicit surfaces, they identified a superior stiffness-weight ratio thickness, periodicity value and low coefficient of thermal expansion with Inconel718.

This Nickel Super Alloy is of higher density than the lower-density aluminum alloy that has been more traditionally used for satellite chassis; using Inconel718 enabled the production of a metal material structure with much finer features as compared to using the aluminum alloy. Application of this ideal structure and material to a lightweight 3U cubesat bus design enabled a lighter and stiffer chassis than would have been possible with the traditional alloy.

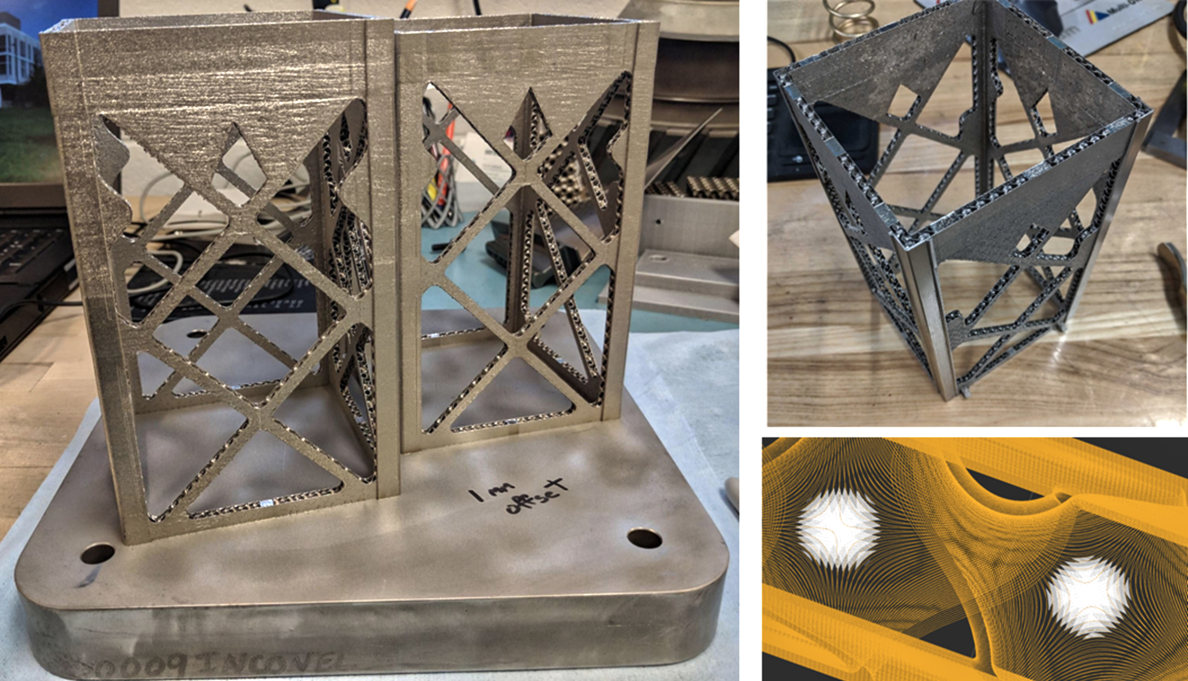

Next, the software’s Direct-To-Manufacture (DTM) capability made it possible to realize the production of the minimized wall thickness design of the cubesat (just 250 microns).

This software-driven, manufacturing output technology provides an unprecedented level of control of the fabrication process that was previously unachievable in other geometry creation and editing software. Inherent to this is the ability to slice the native model to prepare it for manufacturing without the need to generate an intermediate STL file—which historically has created significant speed bumps to production in AM systems.

Quality Parts, Faster

The final key enabling technology associated with the new cubesat bus design was the use of AM through the Laser Powder Bed Fusion (LPBF) process with a Concept laser M2 Cusing machine.

Employing nTopology’s DTM technology and Inconel 718 (Nickel Super Alloy with) it was possible to realize a structure that was half the weight of a similar aluminum alloy design with a 20 percent increase in stiffness.

Image 3. (Clockwise from left) Additively manufactured cubesat bus sections on the build platform as removed from the Concept Laser AM; a top-down view showing the gyroid design inside the extremely thin walls that provided stiffness and durability; a software image showing the complexity of the gyroid design enabled by the implicit-algorithm based, field-driven design technology of nTop Platform.

By designing specifically for additive manufacturing, the researchers were able to reduce the number of parts in their bus design from 150 to less than 25, which represents a 6x reduction in possible failure locations due to vibration-induced loosening of fasteners.

Upon completion of the design, a fully printed and secondarily processed cubesat was achieved in 3.5 business days. The structural bus was evaluated and certified to meet the requirements for launch using a shaker table and NASA GEVS launch profile certification methodology.

With a short delivery time, it is now possible to produce a cubesat structural bus that can be easily reconfigured based on changing satellite mission requirements.

Coupled with the ability to deliver this modularity with increased stiffness and lower weight, this rapid capability represents a revolutionary step forward for the satellite design community.

For the study described here, a 3U cubesat was used for demonstration purposes; however, larger AM machines could be used to enable much larger satellite systems (6U, 12U, 27U, etc.).

This ability to create and produce such advanced structures extremely rapidly is something that can be employed in a variety of aerospace and other industrial applications.

ntopology.com

www.afit.edu