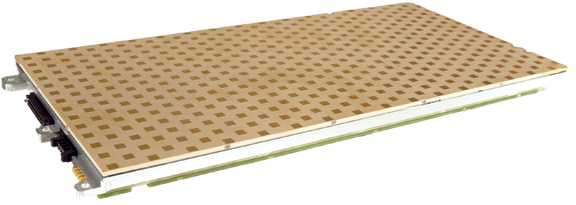

Innovation, the development of a technology that will bring about seismic change to an underserved global mobility connectivity market, has always been at the heart of Phasor as a company. Development of the enterprise-grade electronically steered antenna (ESA) began over five years ago, and today the technology that Phasor has developed is well and truly on the road to commercialization.

The company has recently announced a series of key milestones that will see it moving into a new and exciting phase where its products will bring about a completely new and connected experience to passengers and crew on trains, aircraft, ships, boats, buses and other types of commercial vehicles.

Morgan Stanley projects that the satellite-based, broadband communications market will grow by over 10 times to $400 billion by 2040. There is currently no technology available today that meets the high-performance requirements sought by travelers and operators today who want to chat, stream video, access critical files, keep up with social media and run business applications. This is where Phasor is going to change everything.

Manufacturing

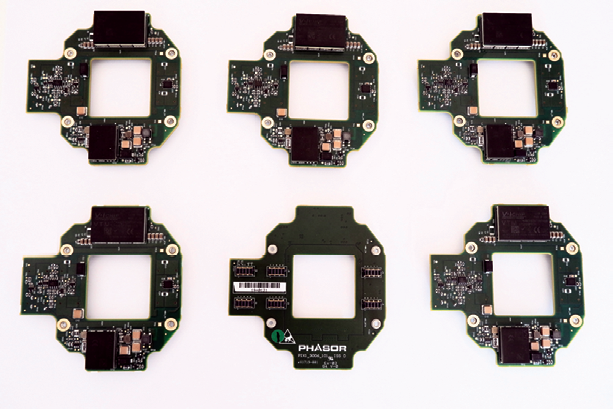

In order to ramp up production, keep on top of the projected demand for the ESA system, and to ensure that the company continues to focus on innovation, Phasor has created a partnership with industry-leading electronics contract manufacturer Surface Technology International, (STI).

The company will bring best-in-class manufacturing capability and will enable Phasor to continue to focus on new technology and product development. In a rapidly expanding market such as mobile broadband, it is important that production is scalable and able to grow with the projected market demand. Therefore, contract manufacturing with a leading partner is a core tenet of Phasor’s strategy.

STI is a specialist Contract Electronics Manufacturer, serving world-class customers in high-reliability industries by providing a complete set of electronics design and manufacturing solutions in both printed circuit board assembly (PCBA) and full box-build manufacturing. The products will be manufactured in the STI Poynton facility, in Cheshire, UK, which is an industry-leading center manufacturing high-quality electronic systems.

Headquartered in Hampshire, UK, and part of the AC Industrials group, STI has decades of experience in the manufacture of complex aerospace, military and SATCOM systems. This will ensure that Phasor can successfully ramp up production as required with a renowned partner that is located within easy reach of Phasor’s London Technology Centre.

A Breakthrough in Power Architecture

Phasor has been working with Vicor, a manufacturer of high efficiency power supply systems, and the two companies have developed a new power architecture that enables Phasor to deliver extremely high current at low voltage, thus ensuring robust mobile communications. The power solution provides connectivity speeds and bandwidth previously unachievable while on the move.

The Factorized Power Architecture™ (FPA) represents a major breakthrough in the delivery of satellite connectivity in aeronautical, maritime, land mobile and defense applications. However, it will also enable the end user traveling on any mode of transportation to enjoy true mobile broadband connectivity, and all the applications that this will enable.

The FPA technology plays an integral role in Phasor’s ESAs and the support of Vicor in the technical innovation of the products helps to differentiate Phasor in what is a very competitive marketplace.

Vicor’s FPA package consists of a Pre-Regulator Module (PRM) and a Voltage Transformation Module (VTM)/Current Multiplier which together deliver the full, regulated, isolated DC-DC converter function. The Voltage Transformation Module (VTM) is a resonant converter and therefore also has very low noise when compared to a hard switched converter.

Vital to realizing performance targets in small and large aperture Phasor ESAs is the ability of Vicor’s systems to transform a 48V supply into a 1.5V supply (1V in the next generation of antenna with even higher current).

Phasor’s desire to make this transformation at 65A (or even 80A) represented a major design challenge for powering its application-specific integrated circuits (ASICs). Offering superior power delivery and efficiency than traditional DC/DC converters, Vicor’s approach to transforming voltage eliminates the need for multiple hard-switching converters with several different phases to attain 65A.

Certification

Phasor recently achieved ISO 9001 Certification before the release of its product range. ISO 9001 is the internationally recognized standard for a quality management system (QMS). This enables companies to operate more effectively on several different levels, including the ability to focus on customer requirements and constantly finding ways in which to improve and become resilient and sustainable.

Why is this significant? It shows Phasor’s evolution from purely development company towards a process-centric commercial products organization. The processes and procedures that have been implemented and also approved by BSI, will enable better management of the business and will demonstrate to customers that Phasor will support them as they grow.

Pushing Boundaries

The Phasor team has one clear aim and that is to make mobile broadband connectivity ubiquitous, while on-the-move, or anywhere on Earth. This new, critical phase towards commercialization means that the company has formed partnerships with others that also share its passion for pushing boundaries, so that more can be achieved.

These relationships enable the companies to share knowledge and to learn so that they can push themselves further — and this is what lies at the foundation of innovation.

www.phasorsolutions.com