If recent forecasts come to pass over the next few years, governments and commercial entities around the world will be placing hundreds of new satellites into orbit—they also will be constructing new ground stations and teleports to manage the satellites and their high-volume data traffic.

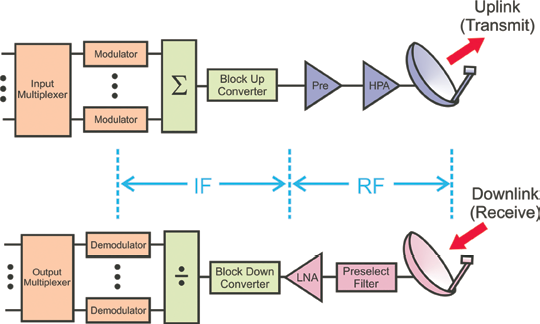

Figure 1. These simplified block diagrams of transmitter and receiver channels illustrate the elements field personnel can measure, characterize and troubleshoot using an all-in-one handheld analyzer.

Ensuring the smooth operation of this new infrastructure will depend on the fast, efficient and cost-effective maintenance and troubleshooting of crucial Earth station equipment. In the past, testing the various radio frequency (RF) and microwave elements has typically required five or six pieces of test equipment, including a spectrum analyzer, a vector network analyzer (VNA) and a cable and antenna tester (CAT).

Today, Keysight’s handheld combination analyzers can replace the full set of instruments previously used for measurements in the field. The latest models can be configured to deliver precise measurements at millimeter-wave frequencies virtually anywhere satellite maintainers need to go.

Outlining The Essential Measurements For Earth Stations

Although every satellite system has two major parts—the space and Earth segments—the focus here is on the Earth-bound side. A ground station sends uplink signals and receives downlinks, and Figure 1 below provides a simplified block diagram that highlights the RF and intermediate frequency (IF) portions of each signal path.

Effective maintenance and troubleshooting requires testing of the overall system and its key elements: antennas, transmitters, receivers and transmission lines. Example measurements include return loss (antenna), fault location (transmission lines), high-power amplifier performance (transmitter), low-noise amplifier (LNA) performance (receiver), and carrier-to-noise measurements (system-level).

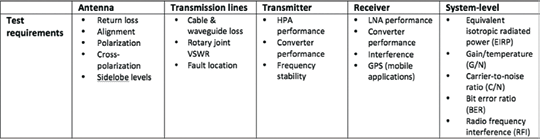

Although Table 1 provides more detail for each major subsystem, these lists are still a subset of what is required for system installation, verification, maintenance, and troubleshooting. Completing the full complement of tests requires six essential instruments: power meter, spectrum analyzer, vector network analyzer (VNA), line sweeper (return loss, distance-to-fault and time-domain reflectometry), RF source, and DC source with voltage and current meter.

Equipping Support Personnel

Users can configure Keysight handhelds to perform CAT, VNA, signal analysis, and more. This range of essential, accurate and timesaving capabilities enables faster diagnosis and repair of faults.

For example, calibrated CAT and VNA measurements help field personnel maintain cable, waveguide and antenna systems consistently and efficiently. Focusing on spectrum analysis highlights the advantages of Keysight’s FieldFox microwave analyzers. For more than 20 years, operators around the world have relied on “portable” spectrum analyzers that were, in reality, a “luggable” solution.

For example, the widely used HP 8565E/EC weighed a hefty 17.3 kg, (38 lbs) and measured 34 x 43 x 19 cm (13.3 x 16.8 x 7.4 in). In contrast, a FieldFox handheld analyzer weighs just 3.2 kg. (7.1 lbs) and measures about 29 x 19 x 7 cm (11.5 x 7.4 x 2.8 in).

These units offer exceptional durability, using a mechanical design that includes no fans or vents. For example, FieldFox has a rugged, fully sealed enclosure that’s compliant with US MIL-PRF-28800F Class 2 requirements. The analyzers have also been type tested to IEC/EN 60529 IP53 requirements for protection from dust and water, extending instrument durability in even the harshest environments.

Warm-up time was another inconvenient aspect of the previous-generation luggable analyzers. This is no longer an issue: with an “instant alignment” feature, a FieldFox microwave analyzer is ready to make highly accurate spectrum measurements at power-up and during ongoing changes over a specified temperature range (e.g., –10 to +55 degrees C or 14 to

131 degrees F). This feature also enables the built-in power meter to make accurate measurements without using an external power sensor.

Carrying Precision Into The Field

Compared to traditional analog designs, a modern digital architecture provides important advantages. For example, there are none of the log-fidelity errors that affect amplitude linearity. Gone, too, are the span-accuracy errors that affect frequency accuracy.

Table 1. This listing of the essential tests for an Earth station is a subset of the total test requirements.

A digital architecture also helps ensure results that match up with those obtained using benchtop analyzers. As a result, today’s best handhelds deliver time- and frequency-domain measurements that correlate with benchmark data acquired using benchtop instruments in the development lab and at system installation. This level of correlation increases confidence in measured results and also reduces the risk of accepting bad systems, subsystems or components, or of failing good ones.

The FieldFox family also supports remote operation through an application that runs on a variety of iOS devices. This feature enables collaboration between personnel, one example being an engineer working at the dish flange and another engineer down below, analyzing measurement results through an iPad or iPhone.

Reducing Capital Expenditures And Operating Expenses

Another benefit of migrating to modern, field-ready technology is a reduction in capital expenditures (CAPEX) and operating expenses (OPEX). Even though a handheld analyzer can replace multiple instruments, some are priced such that each function—CAT, VNA, spectrum analyzer—is about one-half the cost of a comparable benchtop unit. Upfront, this can provide tremendous savings in CAPEX.

A combination analyzer also simplifies the maintenance process, requiring just one calibration per year. This reduces annual OPEX compared to the traditional array of equipment, which may require multiple calibrations per year plus calibrations of any spare instruments. Handhelds that include a standard three-year warranty also reduce the cost of repairs, if needed.

The All-In-One Solution

As new-generation Earth stations come online, handheld microwave analyzers offer a powerful all-in-one solution for field personnel tasked with onsite maintenance and troubleshooting. With a robust array of essential, accurate and timesaving capabilities packed into a portable and durable design, engineers and technicians can be equipped for faster diagnosis and repair of today’s most advanced installations.

Keysight recently introduced a line of six millimeter-wave instruments. The lineup includes three combination-analyzer models that cover 32, 44 or 50 GHz, and there are also three spectrum-analyzer models that cover the same frequencies.

www.keysight.com/find/first50sat

Dan Dunn is a General Manager at Keysight Technologies, responsible for worldwide RF and microwave handheld instruments. He joined Keysight (formerly Agilent Technologies & Hewlett-Packard) in 1995 as an antenna systems engineer. Dan has held various leadership positions at Keysight including marketing manager, global sales manager, product marketing manager and product manager for the 8510 and PNA network analyzer families.

Prior to joining Keysight, Dan worked for Lockheed Martin from 1986 to 1990 as a radar engineer developing test systems for low altitude terrain-following radars for the F-16 and F-15E. From 1990 to 1995, Dan was the Engineering Manager at Technical Systems Associates, an engineering, manufacturing and consulting firm that specialized in the design and development of antennas and tracking systems.

Dan earned Bachelor’s and Master’s degrees in electrical engineering from the University of Central Florida and attended executive education at Harvard University.