Unlike motor vehicles and aircraft, satellites do not lend themselves well to mass production manufacturing due to the specific focus of an individual satellite’s purpose.

HS-333 (Palapa-1)

In particular, a satellite should strike a delicate balance between mass and space availability on the launch vehicle as well meeting the specific payload requirements. As such, many satellites are custom built around mission payloads.

Nevertheless, the techniques of mass production have had some influence in the manufacture of satellites through the adoption of standard platforms to which a customer’s specific requirements are then added.

In particular the USSR/Russia has been using this technique from the early days of space exploration. For instance, the Vostok spacecraft in which Yuri Gagarin made the first crewed spaceflight in 1961 used a space platform that had also been used extensively for a range of other spacecraft. Those included the Zenit 2, Zenit 4, Zenit 6 and Zenit 8 military reconnaissance satellites, as well as their variants, such as the Voskhod three crew spacecraft, of which five were flown (two with a crew), the Bion biological satellites, the Foton materials sciences satellites, the Resurs F series of Earth observation satellites as well as a number of scientific satellites in the Interkosmos and Kosmos series.

The use of a space platform has been mainly limited to communications satellites, which possess a basic platform that contains attitude control, navigation, power supply and other systems, all combined with the specific suite of transponders as specified by the customer.

In the United States, the earliest notion of a satellite platform was introduced by the Hughes Space and Communications Company, which was formed as a subsidiary of Hughes Aircraft in 1961 and remained independent until 2000, when it was purchased by Boeing and became Boeing Satellite Development Center. Apart from building satellites, the company also became involved in the operation of communications satellite services.

Hughes Space and Communications designed and built the world’s first communications satellite in geostationary orbit, known as Syncom-1, and which was launched on February 14, 1963. The platform was known as HS-301 and was used for the entire Syncom series of three satellites. All of these satellites, as well as a number of additional Hughes satellites, were essentially of like design for a single customer.

RCA Astro Electronics, a company that was established in the late 1950s as a division of RCA, was another leading manufacturer of satellites and related systems. It was purchased by General Electric in 1986 and was renamed GE Astro Space, eventually sold to Martin Marietta in 1995—that company merged with Lockheed in 1995 to become Lockheed Martin Space Systems.

RCA Astro Electronics introduced the AS1000 platform on December 13, 1975, followed a few years later by the AS3000 platform on April 7, 1978. However, similar to the early Hughes HS-301 satellites, these were developed for a single customer—the RCA SATCOM branch of the RCA conglomerate of companies.

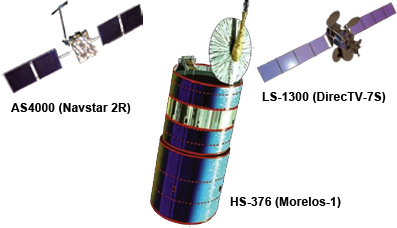

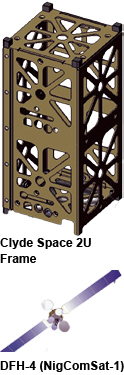

Introduced in 1972, the Hughes HS-333 with a mass of 574kg was the first platform used for communications satellites builds for various operators.

Introduced in 1980, the Hughes HS-376 was the smallest of the spin-stabilized platforms offered by the company. With a typical mass of 654kg, the platform included four hydrazine thrusters with 136kg propellant, a Star 30 apogee kick motor and solar cells mounted on outside of cylindrical satellite body which provided 990W of power and recharged two NiCad batteries. When Hughes was taken over by Boeing, the designation became BSS-376.

Sub-versions were the HS-376HP, a high powered version that was later redesignated as BSS-376HP as well as the HS-376L (for large) and HS-376W (for Wide), which was fitted with a single antenna.

RCA Astro introduced the AS4000 platform in 1985, a three axis stabilized platform with a mass of about 1000kg and fitted with solar arrays. The AS4000 is an excellent example of the versatility of such a platform as, apart from having been used for some communications satellites, it has also been used for the Navstar 2R series of navigational satellites.

The Space Systems Division of Ford Aerospace entered the market in 1989 with the FS-1300 platform. The division was acquired by Loral Corporation in 1990 and became known as Space Systems/Loral, with the platform known as LS-1300.

Since then, the space platform has gone through an evolutionary process to deliver increasingly higher power, greater flexibility and a longer mission life. The earliest models had a mass of 5500kg and required a 4m diameter fairing, whereas current models are 6,700kg and need a 5m fairing. The platform is built using a lightweight and high-strength structure and includes fuel-efficient attitude and attitude control subsystems, high-efficiency and reliable solar arrays and batteries, and advanced command and control subsystems.

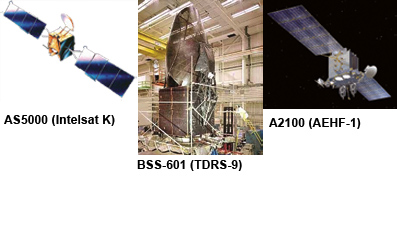

Hughes introduced the HS-601 platform in 1990. The 4135kg platform had a height of 2.29m and a span of 18.30m. It was three-axis stabilized and was fitted with one Marquardt 490 N bipropellant thruster. Twin solar wings of three, 2.16 x 2.54m panels, carried large area silicon cells on Kevlar substrate to satisfy the 3.3kW requirement. It was later designated as BSS-601 and versions included the HS-601HP, a high powered version of the HS-601 that became BSS-601HP, and HS-601M, also known as BSS-601M.

The RCA Astro AS5000 platform was introduced in 1992. With a typical mass of 2850kg, the three axis stabilized satellite had two solar arrays with a span of 24m as well as 20 monopropellant hydrazine thrusters for attitude control.A further development, the AS7000, was introduced in 1993. These satellites were heavier, in the range of 3400kg, and were also fitted with solar arrays.

The A2100 platform entered the market in 1996 and made extensive use of modular subsystem and components, allowing an A2100 based satellite to be delivered within 18 months of having placed an order. It can be configured in four different sizes, identified as A2100A, A2100AX, A2100AXS, A2100AXX and A2100M, the latter for military satellites.

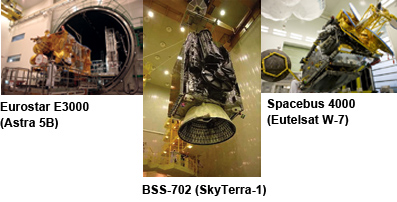

Originally designed as the Hughes HS-702, the Boeing BSS-702 was based on the HS-601 but was more powerful and incorporated a bipropellant propulsion system, which could lift the 5,200kg satellite into final orbit after separation from the launch vehicle. This spacecraft was introduced n 1999 and was adaptable to medium earth and geostationary orbits. Modularity extended to the power system and various configurations of solar arrays could be accommodated.

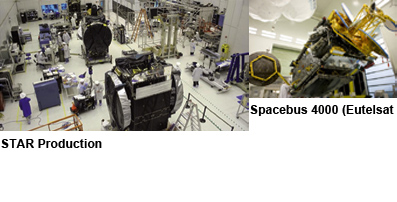

A more recent participant in the development of space platforms has been Orbital Sciences Corporation—the company produces the STAR Bus platform. Measuring 1.75m x 1.70 m x 1.80m and with a basic structure mass of 800-1,500kg, the STAR Bus provides a relatively small platform, compared to some of the other commercially available platforms. This modular design was introduced in 1997 and is based on composite thrust cylinders to which the spacecraft systems and payload are attached, as well as the two solar wings. The STAR platform is compatible with the Ariane 5, Soyuz, Zenit Land Launch, Proton, H2A, Falcon-9 and Zenit Sea Launch vehicles and has a typical mission life time of up to 15 years.

In Europe, Matra Marconi Space was established in 1990 as a joint venture between the space and telecommunication divisions of the Lagardère Group (Matra Espace) and the GEC group (Marconi Space Systems). In 2000, the company merged with the space division of DaimlerChrysler Aerospace AG (DASA) to form Astrium.

Similar to its U.S. counterparts, the first platform produced by Matra Marconi was the Eurostar 1000 that was used for four Inmarsat launches. From that success, Matra Marconi developed the Eurostar 2000, which was introduced in 1991. The platform allows a mass of up to 1900kg and has with a three-axis stabilization. A further version is the Eurostar 2000+ which has a capacity of as much as 2850kg.

The Eurostar E3000 was first used in 2004 and allows a launch mass of up to 6000kg, with solar arrays that span 35 to 45 meters.

Another European company, the Thales Alenia Space corporation, has its heritage in the Alcatel Alenia Space company. The Thales group was established in 2005. The latter company can actually trace its heritage to 1893 when the Thomson-CSF company was established to operate patents of the U.S. Thomson-Houston Electric Corporation in the then-emerging markets of power generation and transmission. Thomson-CSF adopted the name Thales in December of 2000.

Various satellite platforms.

After building the Spacebus 100, 300 and 1000 for select customers, the company introduced the Spacebus 2000 in 1990, followed by the Spacebus 3000 in 1996 and the Spacebus 4000 in 2005. The Spacebus platforms have all been designed with a variety of missions in mind—the latest development, the Spacebus 4000, can be used for payloads of up to 6000kg. They come in a range of versions designated as Spacebus 3000A, B2 and B3 as well as Spacebus 4000 B2, B3, C1, C2, C3 and C4.

In China, the Dongfanghong-4 (DFH-4) platform was designed and built by the China Academy of Space Technology (CAST). Production began in 2001 with the first satellite launched in 2003.

The DFH-4 platform has a payload capacity of close to 600kg and is now extensively marketed in international market as a low-cost alternative to those offered by companies in the United States, Europe and Russia. In particular China is targeting developing countries in Asia, Africa and South America, offering them an all-inclusive package that includes satellite design and fabrication and the launch of the satellite via a Chinese rocket from a designated Chinese launch site.

Other countries that have produced space platforms include India and Russia. However, these platforms have been basically used for single customers and are not (yet) marketed as open market platforms for a variety of customers.

Finally, the recent development of CubeSats has opened up a totally new and growing market of space platforms. Originally designed at the Californian Polytechnic Institute at Cal Poly, San Luis Obispo, California, a broad range of companies now offer CubeSat frames and components as commercial–off-the-shelf (COTS) products and can be acquired at lower costs than a standard satellite platform.

About the author

Jos Heyman is the Managing Director of Tiros Space Information, a Western Australian consultancy specializing in the dissemination of information on the scientific exploration and commercial application of space for use by educational as well as commercial organizations. An accountant by profession, Jos is the editor of the TSI News Bulletin (http://tiros.zarya.info/ ) and is also a regular contributor to the British Interplanetary Society’s Spaceflight journal. Jos is also a Senior Contributor for SatMagazine.