Comes great responsibility — that’s the story many are familiar with in the comic book world of superheroes.

In the maritime communications world, that statement should read, “With greater power comes greater challenges.”

The maritime communications environment has changed dramatically over the past decade. Shipping companies need to promote extreme efficiency on board all of their assets at sea — and they are turning to satellite in order to make this happen. Satellite connectivity allows companies to extend their land-based offices to their vessels and to allow constant communication with all of their ships no matter where in the world they happen to be located.

This is the era of the ‘office at sea’ — and it offers a vast array of benefits to shipping company investors who have been hit by bad economic conditions. Gaining access to a flow of information from their vessels enables them to manage their whole business in a much more efficient manner.

Satellite-based connectivity enables operators to collect data on fuel usage, to monitor the engines, to access weather data, to be able to send data to and from HQ, to access email, voice and other communications services and they want to keep their crew happy. To maintain connectivity, data-centric services are becoming increasingly important. High Throughput Satellites (HTS) allow access to the Cloud, Big Data analytics, automated services, video streaming applications, crew welfare services, and to the popular Bring Your Own Device (BYOD) on board.

These increasing data requirements onboard all types of vessels have pushed service providers to “amp” up the data rates and re-evaluate the network architectures from the ground (or deck) up. This means looking at substantially capable HTS and different modem technologies, such as DVB-S2X, Mx-DMA, and dSCPC.

Today, a new generation of satellites is enabling access to extremely powerful and abundant capacity through most of the major shipping and transit areas around the globe. The new modem technologies facilitate efficient satellite transmission in the order of 10’s to 100’s of Mbps. Yet, as one major satellite hardware manufacturer executive recently said, “In many cases, the throughputs [HTS] cannot be increased because the very expensive stabilized antenna was outfitted with a Block Upconverter (BUC) that was sized for the near-term requirement only and thus becomes a bottleneck for the entire ship.”

There are other reasons in addition to cost to keep the RF power to a minimum. Often, it’s a result of limitations in weight or power consumption. However, newer technologies in RF power are re-shaping the thought process when designing stabilized platforms and as a result, some of the leading service providers, now regularly outfit new maritime terminals with “over the requirement” RF power.

Keep Your Cool

Maritime terminals bring a unique challenge to the satellite industry. They are composed of moving parts and operating in a “hostile” environment. Therefore, the terminals are almost always enclosed in a radome. Radomes are great at providing protection from the elements.

However, they also create another problem for powered equipment — heat. To combat this challenge, many radomes are outfitted with air conditioning if they operate in warmer climates. This solution often results in higher operating costs.

Large radomes also limit the amount of deck space available. Traditionally, attempts to increase RF power meant increasing BUC size, weight and heat output. However, the introduction and more widespread use of Gallium Nitride (GaN) based BUC products have allowed for the increased power without all the added issues.

There’s a lot going on under the typical radome.

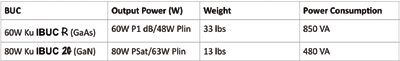

To illustrate this, let’s look at the Terrasat traditional Gallium Arsenide (GaAs) BUC product vs their GaN based product:

This table demonstrates that at similar output powers, the GaN based products are much more efficient and “radome friendly” in terms of weight and power consumption. Another advantage is that GaN based products consume power commensurate with the output at any given time. GaAs BUCs power consumption is either off or at 100 percent. There is no linear progression.

The Correct GaN for the Job

While GaN based products are not appropriate for all applications, such as many multi-carrier operations, the majority of maritime vessels are single carrier uplinks and perfectly suited to the technology. However, customers must be very careful when evaluating GaN BUCs from different manufacturers.

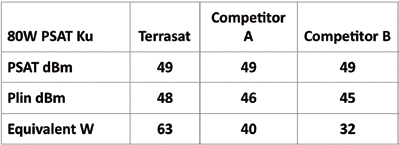

The real output power for GaN BUCs is described as Plin power. This is different from the common power rating for GaAs BUCs, usually denoted as P1dB power. Because GaN technology isn’t as linear (power in = power out) as GaAs technology, Plin is the maximum linear power as defined by MIL STD 188-164B. However, Most BUCs are advertised by their PSAT or P1dB power. The PSAT/Plin discrepancy can lead to a lot of confusion for the “uneducated” end customer. The table below illustrates the difference between BUC manufacturers in the amount of “real” output power (Plin) that is available in various 80W PSAT BUCs on the market.

As you can see, the real output power varies greatly between BUC manufacturers with the same PSAT rating on GaN based BUCs.

Importance of Intelligence

Maritime terminals are, by their nature, remote terminals. Service to the terminal is often available during a service window while in port. Whether you are using GaN or GaAs based technology, the intelligence integrated into the BUC device is increasingly important in today’s networks.

Most large network service providers have adopted sophisticated network management platforms that not only monitor device status and alarms (red, greens and yellows), but they also provide statistics on network uptime, data usage, traffic handling, and applications. Network operators use this information to remotely troubleshoot potential and real-time problems.

Without advanced intelligence in the BUC, a problem could result in failure, and the operator would then have no visibility into the entire site. Operators are then left guessing how to restore operations and usually send a technician to the site blind while carrying a lot of spare equipment. With the increasingly demanding Service Level Agreements (SLAs) that most providers have signed, this situation is untenable.

Terrasat has proactively tackled this issue not only in the design of its IBUC2 range but in the IBUC product line. Every IBUC model has both a microprocessor and sensors placed throughout the unit to monitor functions both internal and external to the IBUC.

Terrasat also provides remote access via SNMP, HTTP, or serial interfaces that provides monitor and control capability of about 70 different functions, facilitating an in-depth view of terminal functions from a Network Operations Center (NOC).

A few of the key Monitor & Control (M&C) parameters found in the alarm functions:

• Input level low/high from the modem

• Output level low/high

• Temperature

• Modem 10 MHz reference detector

In the event of an alarm, the NOC operator can drill down to determine exact levels of these and several other important functions that can impact performance. If issues develop at a terminal, the operator can locally or remotely explore the upgraded event log that now stores 1,000 sensor readings.

Each time-stamped entry contains status readings for power input, power output, 10 MHz reference, power supply conditions and more. Using this information, the operator can detect trends or track events to quickly isolate the cause of the issue – whether internal to the IBUC or from an external source. Fast trouble-shooting equates to fast service restoration.

Demands placed upon maritime network service providers today are greater than ever before. Network design engineers spend most of their time analyzing the various baseband and satellite capacity solutions available, leaving the BUC decision as an outcome of link budgets and pricing considerations. With new technology available, it is now advisable and economical to design in extra RF power for growth and more integrated intelligence for M&C and data analysis.

Terrasat’s forward-thinking and proactive approach allows its customers to take more control with an M&C system that provides in-depth information so that technical issues do not become problems and to ensure that the power is in place for future growth.

terrasatinc.com/